Build a Simple Robot: This guide will take you through the exciting process of creating your own basic robot. From understanding the fundamental components to designing a functional model and integrating sensors, we’ll cover every step. Discover the world of robotics with this comprehensive tutorial.

We’ll start with a clear definition of a simple robot and explore examples in everyday life. Then, we’ll dive into designing your robot, choosing materials, and outlining its mechanical parts. Understanding control systems is crucial, so we’ll look at remote control and programming options. Next, we’ll explore how to integrate sensors to make your robot responsive, followed by a detailed building procedure.

Finally, we’ll test and evaluate your creation, explore real-world applications, and even discuss troubleshooting and maintenance.

Introduction to Simple Robots

A simple robot, in its essence, is a machine that can perform predetermined tasks automatically, often with some degree of autonomy. It typically operates based on pre-programmed instructions and reacts to environmental cues, although the complexity of these responses varies greatly. This contrasts with more sophisticated robots that can adapt to changing conditions and perform more complex functions.These automated systems, despite their apparent simplicity, are crucial in many aspects of our daily lives, from household appliances to industrial processes.

Their ability to perform repetitive or dangerous tasks frees up human time and effort for more creative endeavors. Understanding the basic components and types of simple robots is essential to grasping their significance and the potential for future developments in automation.

Examples of Simple Robots in Everyday Life

Simple robots are prevalent in everyday life, often unacknowledged as such. Vacuum cleaners, for instance, navigate rooms, autonomously following pre-programmed paths or responding to detected obstacles. Automated lawnmowers exhibit a similar characteristic, meticulously cutting grass in a designated area. Even simple toys like remote-controlled cars and toy robots demonstrate rudimentary automation.

Basic Components of a Simple Robot

The construction of a simple robot typically involves a few key components. These include a power source, such as batteries or a mains connection, to provide the necessary energy for operation. A control system, often a microcontroller or a set of integrated circuits, dictates the robot’s actions based on pre-programmed instructions. Sensors, like light sensors or proximity sensors, allow the robot to interact with its environment and adjust its behavior accordingly.

Finally, actuators, such as motors or servos, enable the robot to move and perform tasks.

Comparison of Simple Robot Types

| Robot Type | Description | Typical Applications | Complexity |

|---|---|---|---|

| Toy Robots | These robots are primarily designed for entertainment and educational purposes. They often have limited functionalities and pre-programmed behaviors. | Educational demonstrations, entertainment | Low |

| Educational Robots | These robots are specifically developed for teaching and learning about robotics, programming, and automation. They typically include interfaces and software for programming and control. | STEM education, programming lessons | Medium |

| Household Appliances (e.g., Vacuum Cleaners) | These robots are automated devices designed to perform specific household chores. They use sensors and actuators to navigate and execute their tasks. | Cleaning, lawn care | Low to Medium |

The table above illustrates the varying types of simple robots, highlighting their applications and the relative complexity of their design. Each type serves a distinct purpose, emphasizing the wide range of applications that simple robots encompass.

Designing the Robot

Building a simple robot involves careful consideration of its physical form and the mechanical components that drive its movements. The design choices directly impact the robot’s ability to perform its intended task effectively and efficiently. This section details the design process for a simple line-following robot.A well-designed robot is crucial for successful task execution. Consideration of factors like weight distribution, material strength, and component integration is essential.

This robot’s design prioritizes ease of construction and modification while maintaining functionality.

Robot Physical Form

The robot will have a rectangular base, approximately 15 cm long and 10 cm wide. This shape offers a stable platform for the mechanical components. The robot’s height will be 7 cm, ensuring a compact design without compromising maneuverability. The exterior will be constructed from lightweight yet durable ABS plastic. This material provides a balance between cost-effectiveness and structural integrity.

The chosen dimensions are optimized for navigating confined spaces and following a line effectively.

Building a simple robot is surprisingly fun, and getting your hands dirty with circuits and motors is a great way to learn. While you’re soldering and wiring, you might want to take a break and listen to a new Danny Brown song, Kush Coma , to really get your creative juices flowing. The rhythmic beats will definitely inspire your next robot design.

Back to the soldering iron, let’s get this robot built!

Mechanical Components

This table Artikels the mechanical components of the line-following robot:

| Component | Description | Quantity |

|---|---|---|

| Motors | Small DC geared motors | 2 |

| Gears | Plastic gears for speed reduction | 4 |

| Wheels | Small diameter, hard plastic wheels | 2 |

| Chassis | ABS plastic, rectangular base | 1 |

| Line Sensor | Infrared line sensor | 1 |

The use of small DC geared motors allows for precise control over the robot’s movement. The inclusion of gears reduces the motor speed for smoother and more controllable wheel rotation. Small diameter wheels facilitate maneuverability and responsiveness. The lightweight chassis reduces the robot’s overall weight, making it more agile. The infrared line sensor provides the robot with the necessary input to follow the line.

Movement Mechanisms

The robot employs a rotational movement mechanism. Two small DC geared motors, one for each wheel, are connected to the wheels via the gears. The gears are critical for reducing the speed of the motor output to a suitable level for the wheels. The control system, which will be addressed in a later section, will provide signals to the motors, allowing the robot to move forward, backward, or turn.

This approach allows the robot to follow a line precisely.

Building a simple robot is surprisingly fun! I’ve been experimenting with some basic designs lately, and honestly, it’s been pretty cool. While I was working on the gears and motors, I had to take a break and listen to some awesome new music – check out Nicki Minaj and Ariana Grande’s new song “Bed” listen to nicki minaj and ariana grandes new song bed.

Now, back to the robot project – I’m excited to see how it turns out!

Precise control over the motors, facilitated by the gears and the control system, is crucial for the robot’s ability to follow a line effectively.

Robot Control Systems

Controlling a simple robot involves choosing the best method to guide its actions. This selection depends on the robot’s complexity, the desired tasks, and the resources available. Different control systems offer varying degrees of flexibility and precision. Understanding these systems is crucial for effective robot design and implementation.

Control Methods

Various methods are available for controlling a simple robot. These range from straightforward remote control to sophisticated programmed movements. Each approach has its own set of advantages and disadvantages, influencing the choice based on the specific needs.

- Remote Control: This method allows for direct, real-time manipulation of the robot. A human operator controls the robot’s movements through a remote interface. For instance, a joystick can command the robot’s direction and speed. This method is intuitive and straightforward, ideal for tasks where immediate response is required.

- Programmed Movements: Instead of real-time control, programmed movements allow the robot to execute a predetermined sequence of actions. This is achieved through a series of commands stored in a program. The robot follows these instructions sequentially. This approach offers greater accuracy and repeatability, essential for tasks that need consistent execution, such as picking and placing objects in manufacturing.

Programming Robot Movements

Programming robot movements involves creating a set of instructions that dictate the robot’s actions. These instructions can be relatively simple or complex, depending on the task. For instance, a simple robot might have commands to move forward, backward, turn left, or turn right. More sophisticated robots might need instructions for complex maneuvers or object manipulation.

- Simple Commands: A simple robot might use commands like “forward 10 cm,” “turn 90 degrees,” or “stop.” These commands are easy to understand and implement. Using these commands, a sequence of instructions can be created to guide the robot through a desired path. This is similar to programming a basic video game character.

Control Sequence Flowchart

The flowchart illustrates the control sequence for a simple robot performing a task like navigating a path. It Artikels the steps involved in receiving instructions, interpreting them, executing them, and providing feedback.

Description of the Flowchart: This flowchart visually represents the steps in a robot’s control sequence. It starts with the input of commands, which are then interpreted and translated into actions. The robot executes these actions, and feedback on the execution is collected. This feedback helps in adjusting the next set of instructions. The process loops until the desired task is completed.

Advantages and Disadvantages

Different control methods offer distinct advantages and disadvantages.

| Control Method | Advantages | Disadvantages |

|---|---|---|

| Remote Control | Immediate control, intuitive | Limited flexibility, operator dependence |

| Programmed Movements | High accuracy, repeatability, less operator dependence | Requires programming effort, less flexibility for unexpected situations |

Sensor Integration

Bringing sensory capabilities to your robot is crucial for it to interact meaningfully with its environment. Sensors allow the robot to perceive its surroundings, from light levels to proximity of objects. This enables the robot to navigate, avoid obstacles, and react to changes in its environment. Integrating sensors requires careful consideration of wiring, calibration, and testing.Integrating sensors is not just about adding hardware; it’s about programming the robot to understand and respond to the sensor data.

This response will determine how the robot interacts with its surroundings, making it more intelligent and adaptable. The specific sensor choice and its subsequent programming are crucial to achieving desired functionality.

Sensor Types and Their Applications

A simple robot can be equipped with various sensors to achieve diverse functionalities. The most common types include light sensors, proximity sensors, and touch sensors.

- Light Sensors: These sensors measure the intensity of light in their surroundings. They are useful for tasks such as following a light source, detecting changes in illumination, or navigating based on ambient light levels. For example, a robot designed to follow a light beam in a dark environment would use a light sensor to detect the light beam and adjust its path accordingly.

Such sensors are crucial in autonomous navigation in varying light conditions.

- Proximity Sensors: These sensors detect the presence of objects within a certain range. They are excellent for obstacle avoidance and are crucial for robots navigating cluttered spaces. For instance, a robot navigating a maze would use proximity sensors to detect and avoid walls, ensuring safe navigation. The robot can adjust its path accordingly to avoid collisions.

- Touch Sensors: These sensors respond to physical contact. They are valuable for tasks such as object manipulation, detecting obstacles, or providing feedback to the robot’s actions. A robot arm designed for picking up objects would use touch sensors to confirm object contact and to avoid dropping the object. Such sensors are essential for tasks requiring precision and control.

Wiring and Connections

Correct wiring is essential for sensor integration. Incorrect wiring can lead to malfunction or damage to the sensor or the robot’s control system. Refer to the manufacturer’s specifications for the correct wiring diagrams.

- General Procedure: Connect the sensor’s signal wire to the corresponding input pin on the microcontroller. The power and ground wires should be connected to the power supply and ground of the robot, respectively. Ensure all connections are secure to prevent loose connections that can lead to faulty readings.

Calibration and Testing, Build a Simple Robot

Calibration ensures the sensor readings accurately reflect the environment. Proper testing ensures the sensor functions as expected.

- Calibration: Calibrating the sensor involves adjusting its sensitivity to ensure accurate readings in different light levels, distances, or pressure. This usually involves adjusting the sensor’s threshold values in the robot’s control software. For example, a light sensor might be calibrated to read 0 in complete darkness and 100 in bright sunlight.

- Testing: Test the sensor in various scenarios. For example, place the robot in different light conditions, at varying distances from objects, and apply varying levels of pressure to touch sensors. Monitor the sensor’s readings and the robot’s response to ensure that the sensor is functioning correctly. Compare the readings with known values to validate the accuracy of the readings.

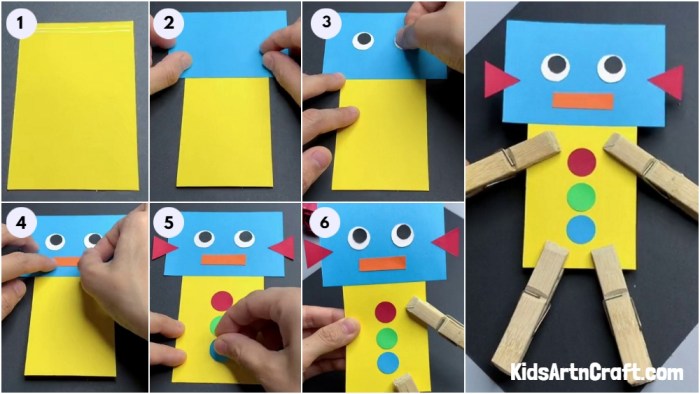

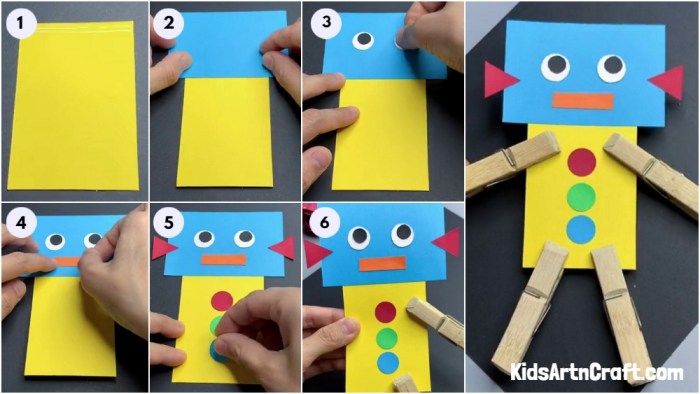

Building the Robot: Build A Simple Robot

Putting together your simple robot is a rewarding experience, allowing you to see your design come to life. This hands-on process reinforces the theoretical concepts learned in the previous sections, making the practical application of knowledge more tangible. Careful attention to detail and adherence to safety procedures are crucial during this stage.Following a methodical approach and understanding the order of assembly is key to success.

Building a simple robot can be surprisingly rewarding, but before you start designing your contraption, it’s crucial to understand the intellectual property landscape. For instance, if you’re planning to use a specific design element, you should definitely check if it’s already protected by copyright, like a pre-existing robot design. Find Out if Something Is Copyrighted This will help you avoid any legal issues down the road.

Knowing the rules will ensure your robot project stays on the right track, and you can focus on the fun parts of building it.

Each step builds upon the previous one, and mistakes early on can have a ripple effect on later stages. This section will guide you through the assembly process, providing clear instructions and a list of necessary tools and materials. Safety is paramount, and this section emphasizes the importance of following safety precautions to prevent accidents.

Assembly Procedure

This section details the step-by-step assembly procedure for your robot. Precise execution of each step is essential for a functional and reliable robot.

- Foundation Preparation: Secure the base plate or chassis, ensuring it’s level and stable. Mark the locations for mounting components to avoid misalignment.

- Motor Installation: Carefully mount the motors to the chassis, using the provided screws and nuts. Ensure the motors are properly aligned and secured. Use a torque wrench to avoid over-tightening and potential damage to the motor or chassis.

- Gearbox Attachment: Connect the gearbox to the motors, ensuring smooth operation and proper alignment. Check for any signs of interference or misalignment. Proper alignment is critical for efficient power transmission.

- Chassis Assembly: Attach all necessary structural components to the chassis, ensuring proper alignment and security. Pay close attention to the provided diagrams and instructions to maintain structural integrity.

- Sensor Integration: Position the sensors according to the design plan. Secure them firmly, avoiding any potential movement or misalignment. Ensure sensors are properly connected to the control system.

- Control System Connection: Connect the control system components to the motors and sensors. Verify the connections using a multimeter to check for proper voltage and current flow. This step is crucial for the robot’s functionality.

- Final Adjustments: Test the robot’s movement and functionality. Make any necessary adjustments to ensure smooth operation and proper sensor response. This step is essential for fine-tuning the robot’s performance.

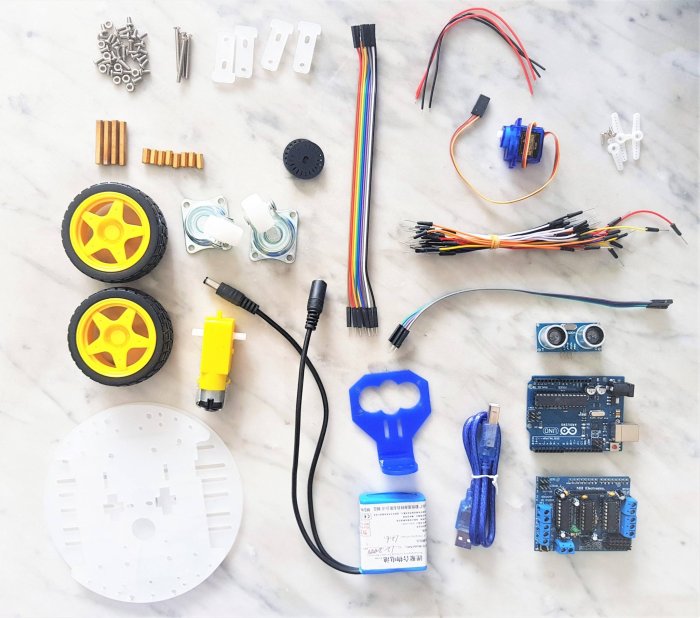

Required Tools and Materials

A well-stocked toolbox is essential for successful robot construction. The following table Artikels the necessary tools and materials.

| Category | Item | Quantity |

|---|---|---|

| Screwdrivers | Phillips head, Flat head | 2 |

| Wrenches | Adjustable | 1 |

| Pliers | Needle nose, side cutting | 1 |

| Drill | Electric | 1 |

| Drill bits | Various sizes | Assorted |

| Nuts and bolts | Appropriate size | Assorted |

| Electrical tape | 1 roll | |

| Cable ties | 1 pack | |

| Materials | Base plate/chassis | 1 |

Safety Precautions

Safety should be a top priority throughout the assembly process. Adherence to safety precautions can prevent injuries and damage to equipment.

- Electrical Safety: Ensure all electrical connections are secure and properly insulated. Never work with electrical components while they are energized.

- Tool Safety: Use appropriate safety glasses and gloves when working with power tools. Maintain a clean and organized workspace.

- Component Handling: Handle all components with care to avoid damage. Follow manufacturer instructions for handling delicate components.

- Environmental Safety: Work in a well-ventilated area, especially when using solvents or adhesives. Store hazardous materials properly.

Testing and Evaluation

Bringing your robot to life requires rigorous testing and evaluation to ensure its functionality and performance meet expectations. This phase is crucial for identifying and addressing any issues before deployment. A well-defined testing strategy helps pinpoint areas needing refinement, leading to a more reliable and efficient robot.

Robot Functionality Testing Method

Thorough testing ensures the robot’s core functionalities are working as intended. This involves a series of predefined tests, covering all programmed actions. Each test should be designed to isolate specific functionalities, allowing for focused evaluation of each component’s performance. This method allows for the systematic identification of any glitches or unexpected behaviors, facilitating the troubleshooting process.

Evaluation Criteria for Robot Performance

Several key criteria are used to evaluate robot performance. These include speed, accuracy, efficiency, and reliability. Speed is measured by the time taken to complete tasks. Accuracy is evaluated by comparing the robot’s output with the expected outcome. Efficiency is assessed by analyzing the resources consumed (power, time) during operation.

Reliability considers the robot’s ability to consistently perform tasks without failures.

Robot Functionality Checklist

This checklist ensures all aspects of the robot are functioning correctly. Its use helps maintain consistency and thoroughness in the testing process.

- Power Supply: Verify the power supply is functioning correctly and providing sufficient voltage to the robot. Ensure the battery is fully charged for tests requiring sustained operation.

- Motor Control: Test the motor control system to verify that each motor operates at the correct speed and direction. Check for any unusual noises or vibrations.

- Sensor Readings: Test the sensors to ensure they are providing accurate readings in various conditions. This includes calibrating sensors to account for environmental factors.

- Programming Logic: Evaluate the correctness of the robot’s programming by executing the pre-defined tasks and monitoring the outputs. Ensure the robot adheres to the desired program logic.

- Safety Mechanisms: Confirm that safety mechanisms, such as emergency stops, are operational and respond appropriately to potential hazards.

Test Results Record

A table is essential for documenting test results and observations, facilitating easy analysis and tracking of progress.

| Test Case | Expected Outcome | Actual Outcome | Observations | Pass/Fail |

|---|---|---|---|---|

| Motor Speed Test | Motor rotates at 100 RPM | Motor rotates at 95 RPM | Slight deviation from expected speed. | Fail |

| Sensor Calibration | Sensor reads 100 units in ideal conditions | Sensor reads 110 units | Sensor reading slightly higher than expected, needs calibration. | Fail |

| Navigation Test | Robot navigates to target location | Robot navigates to target location successfully | Navigation performed accurately. | Pass |

Real-World Applications

Simple robots, though seemingly basic, find numerous applications in various sectors, automating tasks and improving efficiency. Their low cost and relative ease of construction make them attractive for specific, well-defined jobs. From cleaning to manufacturing, simple robots are demonstrating impressive versatility and are constantly evolving to meet new demands.

Cleaning Robots

Simple robots excel in repetitive tasks, such as cleaning. Vacuuming robots, for instance, use sensors to navigate and map a space, automatically cleaning floors. Their design typically involves a chassis with a vacuum system, sensors for obstacle avoidance, and a power source. These robots are frequently found in homes and businesses, reducing the need for manual cleaning and freeing up human workers for other tasks.

Automation in Manufacturing

Simple robots can also play a crucial role in manufacturing. For instance, in assembly lines, simple robots can perform tasks like picking and placing components with precision, increasing production speed and accuracy. These robots are programmed to execute specific actions, such as gripping and transferring objects, ensuring consistency in the manufacturing process.

Agricultural Applications

Simple robots can enhance agricultural practices by automating tasks like planting, weeding, and harvesting. These robots are often designed with specific sensors for detecting soil conditions, plant growth, and pests. This allows for targeted interventions, leading to higher yields and improved resource management. For example, a simple robot equipped with a camera and GPS system can identify and spray weeds without harming crops.

Comparison of Simple Robots

| Type of Robot | Application | Advantages | Disadvantages |

|---|---|---|---|

| Vacuum Cleaning Robot | Home and office cleaning | Reduces manual labor, improves cleanliness, and is often affordable. | Limited to flat surfaces, may not handle complex cleaning situations. |

| Assembly Line Robot | Manufacturing | High precision, consistent output, and increased speed of assembly. | Limited adaptability to changes in assembly procedures, often require complex programming. |

| Agricultural Robot | Planting, weeding, and harvesting | Reduces labor costs, improves yield, and minimizes environmental impact. | Requires specific sensors for detecting soil conditions and crops, cost of development and maintenance can be high. |

Illustrative Examples

Imagine a simple robot designed for cleaning a factory floor. This robot would likely have a small, sturdy chassis equipped with sensors that detect obstacles like equipment and cables. The robot would use a vacuum cleaner to collect debris, navigating autonomously through the designated area. In a different scenario, a small, wheeled robot could be programmed to identify and harvest specific types of fruits in a field, guided by cameras and sensors that differentiate the target fruit from other plants.

The robot’s programming would allow it to precisely grasp and detach the fruit without damaging surrounding crops.

Troubleshooting and Maintenance

Troubleshooting and maintaining a simple robot is crucial for ensuring its longevity and optimal performance. Understanding potential issues and their solutions allows for swift repairs and prevents costly downtime. Proper maintenance also extends the robot’s lifespan and reduces the risk of catastrophic failures.Effective troubleshooting hinges on a methodical approach. Begin by identifying the specific problem. Is the robot not responding, moving erratically, or experiencing power fluctuations?

A systematic analysis of the symptoms will guide you towards the root cause. Following a structured troubleshooting process, using available resources and documentation, is key to a swift resolution.

Common Robot Malfunctions

Simple robots, like many mechanical systems, can experience various malfunctions. Identifying the specific issue is the first step in finding a solution. Common problems include:

- Power Issues: A lack of power or erratic power supply can cause the robot to fail to operate or malfunction. Check the power source, ensure proper connections, and verify the voltage/current requirements for the robot.

- Mechanical Failures: Problems with the robot’s moving parts, such as motors, gears, or axles, can cause unexpected movement, jamming, or complete failure. Inspect the robot’s moving parts for wear, damage, or misalignment. Lubrication can help prevent issues with moving parts.

- Sensor Errors: Sensor malfunctions can lead to incorrect data being sent to the control system. This can cause the robot to react unexpectedly or fail to perform tasks accurately. Check the sensors for physical damage or loose connections. Calibration is often necessary to ensure proper sensor functionality.

- Software Bugs: Programming errors in the robot’s control system can cause unexpected behaviors or failures. Review the robot’s code and ensure it’s functioning as intended. Debugging tools can be very useful in identifying errors.

Maintenance Procedures

Regular maintenance is essential for preserving the robot’s functionality and extending its operational life. Consistent upkeep prevents minor issues from escalating into major failures.

- Cleaning: Regular cleaning of the robot’s components, particularly moving parts and sensors, prevents dust accumulation and debris buildup, which can affect performance and cause damage. Use compressed air to remove dust, and avoid using harsh chemicals or solvents.

- Lubrication: Regular lubrication of moving parts is essential to reduce friction and wear. Use appropriate lubricants as per the manufacturer’s recommendations. This is critical for motor and gear longevity.

- Inspections: Regular visual inspections of the robot’s components are necessary to identify any potential problems early on. Look for signs of wear and tear, such as damaged wires, loose connections, or broken components. This preventive measure can save you significant downtime later.

- Software Updates: Keeping the robot’s control system software up to date is vital. Software updates often include bug fixes and performance improvements, enhancing the robot’s overall reliability and efficiency.

Troubleshooting Guide

This table provides a simplified troubleshooting guide for common issues:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Robot not responding | Power outage, loose connections, software error | Check power supply, ensure all connections are secure, restart the system, check for software updates |

| Erratic movement | Mechanical malfunction, sensor error, software error | Inspect moving parts for damage or misalignment, check sensor readings, debug the software |

| Robot stops unexpectedly | Overheating, mechanical jam, power fluctuation | Allow the robot to cool down, check for blockages in moving parts, ensure stable power supply |

Conclusion

Building a simple robot is a rewarding experience that combines creativity and technical know-how. This guide provides a roadmap to bring your robot vision to life, covering everything from design and construction to testing and troubleshooting. From simple toy robots to more complex automated systems, the possibilities are endless. So, grab your tools, get creative, and embark on this exciting journey into the world of robotics!