Install a Gas Fireplace: This comprehensive guide walks you through every step of the process, from choosing the perfect fireplace to ensuring a safe and efficient installation. We’ll explore different types, fuel options, safety considerations, and the environmental impact, equipping you with the knowledge to make informed decisions.

Whether you’re a seasoned DIY enthusiast or a homeowner tackling this project for the first time, this guide will be your reliable companion. We’ll break down the installation process into manageable steps, providing clear instructions and detailed explanations. Safety will be paramount, and we’ll delve into potential hazards and preventative measures.

Introduction to Gas Fireplaces

Gas fireplaces have become a popular choice for homeowners seeking a warm and inviting ambiance. They offer a convenient alternative to traditional wood-burning fireplaces, providing a quick and efficient way to heat a room. Beyond simple warmth, gas fireplaces come in various styles, each with its own set of advantages and disadvantages. This exploration delves into the different types, fuel sources, benefits, and potential drawbacks of these modern heating solutions.Gas fireplaces are a significant upgrade from traditional wood-burning alternatives.

They offer greater convenience and safety, allowing homeowners to enjoy the ambiance of a fire without the hassle of wood storage, maintenance, and potential chimney issues.

Types of Gas Fireplaces

Gas fireplaces encompass a wide variety of designs and installations. Understanding the different types available is crucial for selecting the best fit for your home and personal preferences. These range from classic log sets to sleek, modern linear models.

- Log Sets: These fireplaces often mimic the appearance of a traditional wood-burning fireplace, using realistic-looking gas logs and often incorporating decorative elements. They are popular for their aesthetic appeal and are often suitable for various room styles.

- Linear Fireplaces: These models feature a long, continuous flame that often runs along a wall or a section of a room. They are known for their sleek design and often allow for a more modern look. This design can effectively heat larger spaces due to the efficient distribution of the heat.

- Wall-mounted Fireplaces: Designed to be installed directly on a wall, these are typically compact and efficient, taking up minimal space while still providing warmth and ambiance.

Fuel Types

Gas fireplaces utilize various fuel sources. The choice of fuel often impacts the cost of installation, maintenance, and the overall efficiency of the fireplace.

- Natural Gas: This is the most common fuel source for gas fireplaces, often directly connected to the home’s existing natural gas pipeline. This provides a consistent and readily available fuel supply, making it a popular option.

- Propane: For homes without natural gas access, propane gas is a viable alternative. Propane fireplaces require a propane tank, which necessitates regular refills and potential storage space considerations. Propane is also often more expensive than natural gas.

Benefits of Gas Fireplaces

Gas fireplaces offer several advantages over other types of heating solutions.

Installing a gas fireplace can be a rewarding project, transforming a room with its warm glow. While you’re admiring the cozy ambiance, consider putting on some chilled tunes, like the mellow soundscapes of the minimal wave tapes volume 2. The perfect background music for the soothing process will enhance the whole experience. After all, a properly installed gas fireplace adds a touch of elegance and comfort to any home.

- Convenience: Gas fireplaces provide a quick and easy way to heat a room. They require minimal effort to operate compared to wood-burning alternatives, as they are simple to ignite and maintain.

- Efficiency: Gas fireplaces are designed for efficient heat output, allowing for controlled temperature and minimal wasted energy.

- Cleanliness: Gas fireplaces produce minimal soot or ash, eliminating the need for frequent cleaning and maintenance.

Drawbacks of Gas Fireplaces

Despite the advantages, gas fireplaces also have some drawbacks to consider.

- Cost of Installation: Installing a gas fireplace can be a substantial investment, requiring professional installation to ensure safety and compliance with local regulations.

- Potential Safety Concerns: Gas fireplaces, if not properly installed and maintained, can pose safety risks related to gas leaks or improper operation. Regular safety checks are essential to mitigate these concerns.

Comparison Table

| Type | Fuel | Pros | Cons |

|---|---|---|---|

| Log Sets | Natural Gas/Propane | Aesthetically pleasing, often mimics traditional wood-burning fireplaces | Can be more expensive to install, less efficient heat distribution compared to linear models. |

| Linear | Natural Gas/Propane | Sleek design, efficient heat distribution, suitable for larger spaces | May not be suitable for all aesthetics, installation can be complex |

| Wall-mounted | Natural Gas/Propane | Space-saving design, often a cost-effective option | May not provide the same heat output as larger models, less visually striking |

Installation Process

Installing a gas fireplace is a significant undertaking that requires careful planning, meticulous execution, and adherence to safety regulations. It’s crucial to understand the entire process from initial preparation to final connections to ensure a safe, efficient, and aesthetically pleasing installation. Incorrect installation can lead to safety hazards, performance issues, and potential damage to your home. Properly trained and licensed professionals are highly recommended for this task.

Initial Preparation, Install a Gas Fireplace

Before any installation work begins, thorough preparation is paramount. This involves assessing the area where the fireplace will be installed, confirming adequate venting and gas supply, and ensuring the necessary permits are obtained. Proper planning minimizes potential complications and ensures a smooth installation process. The installation area must be clear of obstructions, allowing for easy access and movement of equipment.

- Verify the gas supply line’s capacity and suitability for the fireplace’s needs. Consult with local gas companies to confirm the required pressure and flow rate.

- Determine the proper location for the venting system, considering factors like height, clearance, and accessibility. Ensure the vent system aligns with local building codes.

- Obtain necessary permits and inspections from the local authorities to ensure compliance with building codes and safety regulations. Failure to do so could lead to costly delays or even project rejection.

- Inspect the existing framing and ensure it can support the fireplace’s weight and installation requirements. Reinforcements might be necessary in certain cases.

Safety Precautions

Safety should be a top priority throughout the entire installation process. Understanding and adhering to safety precautions is crucial for avoiding potential accidents and ensuring the well-being of all involved. Never compromise safety for convenience or speed.

- Always turn off the gas supply to the area before starting any work related to gas lines. This is an absolute necessity to prevent accidental gas leaks.

- Ensure proper ventilation throughout the installation area. Adequate airflow helps to prevent the accumulation of flammable gases.

- Wear appropriate safety gear, including gloves, safety glasses, and sturdy footwear, to protect yourself from potential hazards during the installation process.

- Never work alone, especially when dealing with gas lines or electrical connections. Always have a second person present to assist with tasks and monitor safety procedures.

Installation Steps

The installation process involves a series of carefully orchestrated steps. Following these steps in the correct order is essential for a successful and safe installation.

Installing a gas fireplace can be a fantastic upgrade for any home, adding warmth and ambiance. While you’re enjoying the cozy atmosphere, why not crank up the volume with some seriously good tunes like keep it goin louder ft nina sky and ricky blaze ? It’s a perfect way to set the mood for those chilly evenings, complementing the new fireplace’s inviting glow.

Just remember to prioritize safety when handling gas appliances.

- Framing and Structure Preparation: Carefully mark the fireplace’s location and cut the necessary openings in the wall or floor. Reinforce the framing to support the fireplace unit’s weight. Ensure the structural integrity of the area.

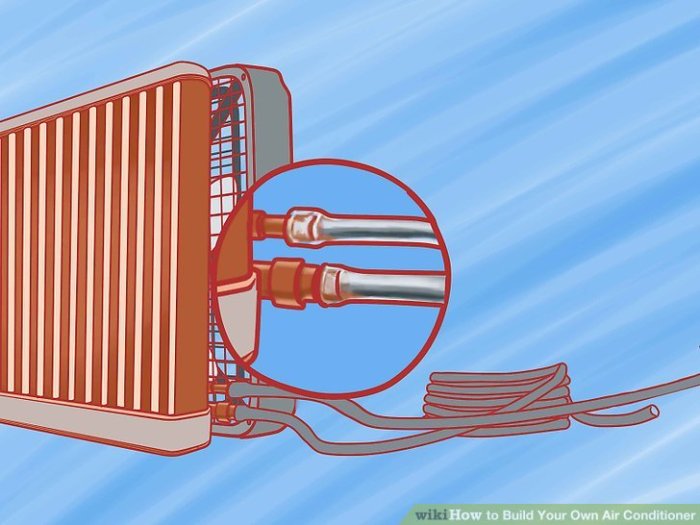

- Plumbing Connections: Connect the gas supply line to the fireplace’s gas valve, ensuring a secure and leak-proof connection. Use approved fittings and follow manufacturer’s instructions carefully.

- Venting System Installation: Install the venting system according to the manufacturer’s instructions and local codes. Proper venting is critical for safe and efficient gas combustion.

- Fireplace Assembly: Assemble the fireplace components according to the manufacturer’s instructions. Pay close attention to the alignment and proper placement of all parts.

- Electrical Connections: Connect the electrical components, if any, to the fireplace and ensure proper grounding. Use approved electrical wiring and connectors.

- Final Checks and Inspections: Perform a thorough check for leaks, ensuring all connections are secure and sealed. Request a final inspection from the local gas and building authorities.

Tools and Materials

The following table Artikels the tools and materials required for each stage of the installation process.

| Step | Tool | Material | Description |

|---|---|---|---|

| Framing and Structure Preparation | Measuring tape, saw, level, drill | Framing materials, screws, anchors | Tools for marking and cutting openings. Materials for reinforcement. |

| Plumbing Connections | Adjustable wrench, pipe cutter, Teflon tape | Gas pipe, fittings, gas valves | Tools for connecting gas lines and materials for leak-proof connections. |

| Venting System Installation | Vise grips, measuring tape | Vents, flashing, insulation | Tools for securing vents and materials for weatherproofing and insulation. |

| Fireplace Assembly | Screwdrivers, adjustable wrench | Fireplace components, screws | Tools for assembling the fireplace. |

Safety Considerations

Installing a gas fireplace is a rewarding project, but safety should always be paramount. Understanding potential hazards and implementing preventive measures is crucial for a safe and enjoyable experience. This section details essential safety considerations to ensure a risk-free installation and operation.Properly installed and maintained gas fireplaces are generally safe. However, potential hazards exist, particularly if the installation or maintenance procedures are not followed meticulously.

Careless handling of gas lines, inadequate ventilation, or faulty components can lead to significant risks. This section focuses on mitigating these risks by highlighting safety precautions and best practices.

Potential Hazards of Gas Fireplaces

Gas fireplaces, while aesthetically pleasing, present inherent safety risks if not handled correctly. These risks stem from the flammable nature of natural gas or propane used in the appliance. Faulty connections, inadequate ventilation, or improper installation can lead to gas leaks, fires, or carbon monoxide poisoning. It’s critical to identify potential hazards to mitigate them effectively.

Importance of Proper Ventilation

Adequate ventilation is essential for safe gas fireplace operation. Incomplete combustion of the gas can produce carbon monoxide, a colorless, odorless, and toxic gas. Insufficient ventilation can lead to dangerous levels of carbon monoxide accumulating in the room, posing severe health risks. Ensure the fireplace is installed in a location with adequate air exchange to prevent the buildup of harmful gases.

Preventing Gas Leaks

Gas leaks are a serious concern, potentially leading to explosions or fires. Regular inspections of gas lines, connections, and fittings are crucial to prevent leaks. Inspecting the gas supply lines for any cracks, corrosion, or loose connections is vital. Leaks can occur at various points, including the gas supply pipe, the gas valve, and the appliance itself.

Installing a gas fireplace can be a rewarding DIY project. It’s a great way to add warmth and ambiance to your home. Before you start, however, you might want to make sure your Spotify account is all set up – Log in to Spotify to ensure you’ve got your favorite tunes ready to play as the fire crackles.

Once you’ve got that sorted, you can focus on getting your new gas fireplace installed properly and safely.

Frequent visual checks and professional inspections are necessary to ensure the safety of the gas lines.

Handling Gas Leaks

In the unfortunate event of a gas leak, immediate action is critical. Never attempt to approach or ignite the area if a leak is suspected. First, evacuate the building immediately. Alert the appropriate authorities, such as the fire department or gas company, and follow their instructions precisely. Turn off the gas supply at the main valve if it is accessible and safe to do so.

Never use any open flames or electrical devices near the leak until the gas company personnel have confirmed the leak is contained and resolved.

Maintaining Gas Fireplace Safety

Regular maintenance is crucial for maintaining the safety of your gas fireplace. Professional inspections are essential to detect and address potential problems. Perform visual inspections regularly for signs of damage or wear to the gas lines, components, and the appliance itself. Follow the manufacturer’s guidelines for cleaning and maintenance procedures.

Safety Checks Before and After Installation

Regular safety checks are essential for ensuring the gas fireplace remains operational safely.

| Check | Procedure |

|---|---|

| Gas supply line integrity | Visually inspect for cracks, corrosion, or loose connections. |

| Gas appliance connections | Verify all connections are tight and secure. |

| Ventilation system | Ensure adequate air intake and exhaust for proper combustion. |

| Carbon Monoxide (CO) detector | Verify the presence and functionality of the CO detector. |

| Gas valve operation | Test the gas valve operation to ensure proper shut-off mechanisms. |

| Post-Installation Inspection | Have a qualified technician perform a final inspection. |

Maintenance and Troubleshooting: Install A Gas Fireplace

Keeping your gas fireplace in top condition requires regular maintenance. Neglecting this can lead to safety hazards, reduced efficiency, and costly repairs down the line. A well-maintained fireplace will provide years of enjoyable warmth and ambiance.Regular maintenance is crucial for the safe and efficient operation of a gas fireplace. It ensures that the appliance functions as intended, minimizes the risk of malfunctions, and helps to extend its lifespan.

By following a simple maintenance routine, you can significantly reduce the chance of costly repairs and enjoy a reliable source of warmth and comfort.

Importance of Regular Maintenance

Regular maintenance is essential to prevent potential problems and ensure safe operation. It involves inspecting and cleaning various components to maintain optimal performance and prevent gas leaks, carbon monoxide buildup, and other safety issues. Proper maintenance also enhances the efficiency of the fireplace, optimizing its heat output and reducing energy consumption.

Common Maintenance Procedures

A regular maintenance schedule involves several key procedures. These include checking the gas supply lines for leaks, ensuring proper airflow, and cleaning the heat exchanger and burner assembly. Regular inspections of the pilot light and ignition system are vital for consistent operation. Furthermore, proper ventilation is critical for the safe and efficient operation of the fireplace, preventing dangerous buildups of combustion gases.

- Gas Supply Line Inspection: Visually inspect all gas supply lines for any signs of damage, leaks, or corrosion. Use a soapy water solution to detect leaks, as a small bubble indicates a potential leak. If any issues are found, contact a qualified professional immediately.

- Airflow Check: Ensure proper airflow to the fireplace by inspecting the vents and openings. Blockages can impede combustion and reduce efficiency. Keep the area around the fireplace clear of obstructions.

- Heat Exchanger and Burner Cleaning: Clean the heat exchanger and burner assembly regularly to remove soot and debris. This helps maintain optimal heat transfer and prevents inefficient operation. Follow the manufacturer’s instructions for safe cleaning procedures.

- Pilot Light and Ignition System Inspection: Inspect the pilot light and ignition system to ensure proper function. Ensure the pilot light is lit and the ignition system is operating correctly. Address any issues immediately.

- Ventilation Check: Ensure proper ventilation to prevent the buildup of combustion gases. Check for any obstructions in the venting system and make sure the vents are unobstructed.

Troubleshooting Common Gas Fireplace Issues

Troubleshooting common issues can often be done safely and effectively by homeowners. By understanding the potential causes of problems, you can identify and fix many issues without professional intervention. A thorough understanding of the system’s components will enable homeowners to diagnose problems more accurately and effectively.

- Pilot Light Won’t Light: Verify the gas supply, ensure the igniter is functioning correctly, and check for any obstructions in the gas line or burner assembly. If the problem persists, contact a qualified professional.

- Fireplace Won’t Ignite: Check for proper airflow, gas supply, and ignition system issues. Ensure the igniter is functioning correctly and that there are no blockages. If the problem persists, consult a professional.

- Unusual Noises: Unusual noises, such as clicking, popping, or hissing, may indicate a problem with the igniter, gas valve, or burner assembly. Check for loose connections or obstructions and contact a professional if the issue persists.

Troubleshooting Procedure Example

To troubleshoot a gas fireplace that won’t ignite, first, ensure the gas supply is turned on and check the gas valve for any obstructions. Next, verify that the pilot light is properly lit. If the igniter clicks but the pilot light won’t light, inspect the igniter’s electrodes for cleanliness. If the issue persists, consult a qualified technician.

| Problem | Cause | Solution | Prevention |

|---|---|---|---|

| Pilot light won’t stay lit | Low gas pressure, dirty burner, or faulty igniter | Check gas pressure, clean burner, replace igniter if needed | Regular cleaning and inspection of burner and igniter |

| Fireplace won’t ignite | Blocked air intake, faulty igniter, low gas pressure | Clear air intake, replace igniter, check gas pressure | Regular cleaning and inspection of air intake and igniter |

| Hissing or popping sounds | Loose connections, gas leaks, or faulty valve | Tighten connections, check for leaks, replace valve if needed | Regular inspection of connections and valves |

Choosing a Gas Fireplace

Choosing the right gas fireplace for your home is a significant decision, impacting both aesthetics and functionality. It’s crucial to consider various factors to ensure the fireplace seamlessly integrates into your existing décor and provides the desired ambiance and warmth. A well-chosen fireplace can elevate a room, while a poorly chosen one can detract from the overall design.Selecting a gas fireplace involves more than just picking a pretty face.

Careful consideration of size, style, features, and budget are vital to achieving a harmonious and efficient addition to your living space. Understanding these factors will help you make an informed decision that perfectly complements your home’s unique characteristics.

Factors to Consider

A comprehensive evaluation of the available options is crucial for a successful installation. Factors such as the fireplace’s overall aesthetic appeal, compatibility with the room’s existing design, and its functional capabilities significantly influence the decision-making process.

- Aesthetic Harmony: Matching the fireplace’s style to the room’s existing design is paramount. A modern fireplace in a traditional room would likely clash, while a rustic fireplace in a contemporary setting could achieve a striking juxtaposition.

- Room Dimensions: The fireplace’s size should be proportionate to the room’s dimensions. A massive fireplace in a small room can overwhelm the space, while a compact fireplace in a large room might appear insignificant. Careful measurement and planning are crucial to avoid such issues.

- Desired Features: Consider the specific features you desire, such as different types of fuel sources, adjustable heat settings, and various decorative options. A fireplace with multiple features will enhance its functionality, but can also increase the overall cost.

- Budget Constraints: Gas fireplaces vary significantly in price, ranging from budget-friendly models to high-end, elaborate designs. Establishing a realistic budget early on will help narrow down the selection and prevent financial overruns.

Styles, Sizes, and Features

Gas fireplaces come in a wide array of styles, sizes, and features, allowing for customization to match any desired aesthetic.

- Styles: Gas fireplaces are available in a diverse range of styles, including traditional, contemporary, rustic, and modern. Careful consideration of the existing home decor will help determine the most suitable style.

- Sizes: Gas fireplaces are offered in various sizes, from compact units suitable for smaller rooms to larger models designed for expansive living spaces. The size of the fireplace should be proportionate to the room’s dimensions to ensure a balanced look.

- Features: Features can include adjustable heat settings, different fuel sources (e.g., natural gas, propane), decorative glass options, and remote controls. These options can significantly enhance the fireplace’s usability and visual appeal.

Brand and Model Comparisons

Comparing different brands and models is crucial for finding the ideal fireplace. Researching customer reviews and examining technical specifications will help determine the best fit for your needs.

| Design | Features | Dimensions (approx.) | Price Range (USD) |

|---|---|---|---|

| Traditional Mantel | Adjustable heat, remote control, decorative glass | 36″W x 48″H x 18″D | $1,500 – $3,000 |

| Modern Sleek | Built-in thermostat, remote control, hidden controls | 48″W x 60″H x 12″D | $2,500 – $5,000 |

| Rustic Log Set | Natural gas, adjustable heat, electronic ignition | 42″W x 54″H x 24″D | $1,800 – $4,500 |

| Contemporary Wall-Mount | Propane gas, variable heat, remote control | 30″W x 42″H x 8″D | $1,000 – $2,500 |

Cost and Budget

Installing a gas fireplace is a significant investment, and understanding the associated costs is crucial for budgeting. Factors like the type of fireplace, features, installation complexity, and local labor rates all influence the final price tag. Careful planning and research can help you avoid unpleasant surprises and stay within your budget.

Average Installation Costs

The average cost for installing a gas fireplace ranges from $3,000 to $8,000. This broad range encompasses various factors, including the size and complexity of the fireplace, the materials used, and the labor costs. Installation in a new home often involves more extensive work than retrofitting an existing space.

Costs of Different Gas Fireplace Types

Different types of gas fireplaces have varying price points. For instance, a simple, traditional gas fireplace with basic features will likely cost less than a more sophisticated model with features like remote control, enhanced flames, or specialized venting systems. The materials used and the level of customization also affect the overall cost.

Cost Breakdown Examples

A typical cost breakdown for a gas fireplace installation might include the cost of the fireplace itself, professional installation labor, venting materials (if required), and any necessary modifications to the existing structure. For example, a more complex installation involving a custom mantel, chimney modifications, or extensive plumbing work will naturally increase the overall cost. Similarly, the price of the fireplace itself can vary considerably depending on the manufacturer and the features.

Estimated Gas Fireplace Installation Costs

| Item | Cost | Notes |

|---|---|---|

| Fireplace unit (basic model) | $1,500 – $3,000 | Price varies greatly based on size, features, and brand. |

| Installation labor | $1,500 – $3,500 | Labor costs depend on the complexity of the installation and local rates. |

| Venting system (if needed) | $500 – $1,500 | Chimney work or venting modifications can add significantly to the cost. |

| Plumbing and gas line connections | $500 – $1,000 | These costs vary depending on the complexity of the gas line connection. |

| Permitting and inspections | $100 – $500 | Local regulations influence permitting fees. |

| Total Estimated Cost | $4,000 – $9,000 | A broad estimate covering various installation scenarios. |

Environmental Impact

Gas fireplaces, while offering a cozy ambiance, come with environmental considerations. Understanding their impact on the environment, alongside comparisons to other heating methods, is crucial for responsible decision-making. Choosing a heating source involves evaluating factors beyond just comfort and cost.Gas fireplaces, like any fuel-burning appliance, release emissions into the atmosphere. The type of gas used, the efficiency of the fireplace, and even the maintenance practices play significant roles in determining the environmental footprint.

Comparing their impact with alternative heating options reveals a nuanced picture.

Gas Type and Emissions

Different types of natural gas have varying emission profiles. Methane, the primary component of natural gas, is a potent greenhouse gas. Propane, another common gas used in fireplaces, also releases greenhouse gases, although the specific composition and concentrations may differ. Furthermore, incomplete combustion, often a byproduct of improper maintenance or appliance design, can lead to the release of harmful pollutants like carbon monoxide and nitrogen oxides.

Understanding these differences helps in making informed choices.

Comparison to Other Heating Options

Electric heating, often touted as environmentally friendly, relies on electricity generation, which, depending on the source, may not always be carbon-neutral. Wood-burning stoves, while often perceived as a more natural heating source, contribute to air pollution through particulate matter emissions. Furthermore, their environmental impact also depends on the source of the wood and the efficiency of the stove.

Energy Efficiency of Gas Fireplaces

The efficiency of gas fireplaces is a crucial factor in evaluating their environmental impact. Highly efficient models, often incorporating advanced combustion technologies, minimize the amount of fuel wasted as emissions. This is reflected in the efficiency rating of the appliance, typically expressed as a percentage. For instance, a 90% efficient fireplace uses 10% less fuel to produce the same amount of heat compared to a 70% efficient one.

Higher efficiency ratings directly translate to lower greenhouse gas emissions and a reduced environmental impact.

Environmental Impact Comparison

| Heating Source | Emissions | Energy Efficiency |

|---|---|---|

| Natural Gas Fireplace (High Efficiency) | Methane, nitrogen oxides (variable based on combustion efficiency) | 90%+ (typical) |

| Electric Resistance Heating | Emissions from electricity generation (variable depending on source) | 95%+ (typical) |

| Wood-Burning Stove (High Efficiency) | Particulate matter, carbon monoxide (variable based on combustion efficiency) | 60-80% (typical) |

Note: Efficiency percentages are approximate and can vary based on model and usage. Emissions are general indicators and can vary based on specific conditions and maintenance practices.

Visual Representations

Gas fireplaces, whether modern or traditional, offer a captivating visual appeal that transforms a room. Their design choices, from the materials used to the layout of the installation, greatly influence the overall aesthetic and ambiance. Understanding these visual elements is crucial to choosing a fireplace that complements your home’s style and personality.

Modern Gas Fireplace Installation

Modern gas fireplaces often feature sleek, minimalist designs. Materials used in these installations frequently include high-quality metal, such as brushed stainless steel or polished aluminum, for the fireplace enclosure and surround. Glass panels, often tempered and heat-resistant, are common, allowing for a clear view of the flames. The layout is frequently integrated into the existing room design, blending seamlessly with the architecture.

For instance, a modern installation might feature a floating mantel or a recessed fireplace built into a wall, maximizing space and minimizing visual clutter. The fireplace’s design can often include integrated lighting systems, enhancing the ambiance.

Traditional Gas Fireplace Design

Traditional gas fireplaces evoke a cozy and inviting atmosphere. These installations often incorporate intricate details, such as ornate mantels, decorative surrounds made of stone, brick, or tile, and detailed metalwork. The overall design often emphasizes warmth and craftsmanship, evoking a sense of heritage. The fireplace’s layout is typically more prominent in the room, acting as a focal point, and the design frequently incorporates a larger, more substantial hearth.

Many traditional designs incorporate cast iron or wood accents.

Gas Fireplace in a Contemporary Setting

A gas fireplace in a contemporary setting can be a stylish centerpiece. Consider a setting with clean lines and a neutral color palette. The fireplace itself might feature a minimalist design with a large glass viewing area. The surround could be a sleek, light-colored stone or a modern tile pattern that matches the room’s decor. The surrounding lighting should be carefully considered to highlight the fireplace’s beauty.

Ambient lighting, such as recessed lighting or strategically placed sconces, can complement the fireplace’s design.

Gas Fireplace Designs

Different gas fireplace designs offer various aesthetic possibilities. One design might showcase a linear, elongated fireplace, while another could feature a more rounded, curvaceous shape. Some designs emphasize the hearth and surround, creating a warm, inviting focal point. Other designs focus on the flames, using a larger glass viewing area for maximum visual impact. The fireplace’s finish, whether polished metal, stone, or tile, can also be tailored to match the surrounding room’s design.

Installation in a Living Room

A gas fireplace in a living room adds a unique element to the space. The installation can be a focal point or integrated into the existing decor. For example, in a living room with a warm, rustic theme, a stone-encased gas fireplace with a wood-burning mantelpiece might complement the existing design. The surrounding decor should complement the fireplace’s style.

Warm wood tones, comfortable seating, and soft lighting can create a cozy atmosphere. If the room’s design is contemporary, a modern gas fireplace with clean lines and a neutral color palette would work well. Natural lighting and ambient lighting fixtures can be integrated with the design to maximize the visual impact of the fireplace.

Final Review

In conclusion, installing a gas fireplace is a significant undertaking, but with careful planning, adherence to safety guidelines, and a well-researched approach, it can be a rewarding home improvement project. This guide has provided a comprehensive overview of the entire process, from initial selection to ongoing maintenance. Remember to prioritize safety throughout the entire installation and remember that ongoing maintenance is key to long-term enjoyment of your new fireplace.

![How to Remove Stickers from Wood [10 Easy Ways] Get Stickers off Wood](https://owlgriffin.com/wp-content/uploads/2025/06/how-to-remove-stickers-from-wood-1.jpg)