Test a Ground Rod is crucial for ensuring the safety and efficiency of electrical systems. This comprehensive guide delves into the intricacies of ground rod testing, from understanding their purpose and types to the practical steps involved in testing, troubleshooting, and maintenance. We’ll cover everything from selecting the right testing methods to interpreting results and addressing potential issues.

Ground rods are essential components in electrical systems, acting as a path for fault currents to flow safely into the earth. Their proper function is critical for protecting equipment and personnel from electrical hazards. Understanding how to effectively test a ground rod is paramount to maintaining a safe and reliable electrical infrastructure.

Introduction to Ground Rod Testing

Ground rods are essential components in electrical systems, acting as a low-resistance path for fault currents to flow into the earth. This crucial connection ensures the safety of personnel and equipment by preventing dangerous voltage buildup. Their proper function is paramount to a safe and efficient electrical system.Proper ground rod testing is vital for ensuring the integrity of the grounding system.

Without regular checks, a failing ground rod can lead to safety hazards, such as electric shock, and compromise the reliability of equipment. Furthermore, an ineffective ground rod can lead to higher operating costs and downtime as equipment malfunctions due to inadequate protection.

Ground Rod Functionality

Ground rods, often made of copper or steel, are driven into the earth to establish a low-impedance connection to the earth’s vast conductive mass. This connection is crucial for diverting fault currents away from electrical equipment and personnel, preventing dangerous voltage levels. The conductivity of the soil surrounding the ground rod plays a significant role in its effectiveness. Soil conditions can vary greatly, affecting the ground rod’s resistance to the earth.

Types of Ground Rods

Different materials and designs of ground rods exist, each with varying characteristics. Common types include copper rods, galvanized steel rods, and driven electrodes, each having its unique advantages and disadvantages.

- Copper rods offer high conductivity, but they are often more expensive than steel.

- Galvanized steel rods provide a good balance of cost and conductivity, making them a popular choice.

- Driven electrodes, sometimes composed of multiple rods, are used in specific applications and can achieve very low resistance values.

Ground Rod Failures

Several factors can contribute to the failure of a ground rod to function effectively. These include corrosion, soil resistivity changes, and physical damage.

- Corrosion of the ground rod material, especially in corrosive environments, can significantly increase the resistance of the ground connection. This often results in an ineffective ground connection.

- Changes in soil conditions, such as an increase in soil resistivity, can impede the flow of current to the earth, thereby increasing the ground resistance.

- Physical damage to the ground rod, such as bending or breaking, can also lead to increased resistance and compromised grounding.

Ground Rod Testing Methods

Various methods exist for evaluating the effectiveness of ground rods. Each method has unique advantages and limitations.

| Testing Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Resistance Measurement | Directly measures the resistance between the ground rod and a reference point. | Simple, relatively inexpensive, widely available equipment. | Accuracy depends on the quality of the measuring equipment and the soil conditions. |

| Fault Current Injection | Involves injecting a known fault current into the ground rod system to assess its ability to handle a fault. | Provides a realistic simulation of fault conditions, showing the system’s performance under load. | More complex setup, potentially hazardous if not performed correctly. |

| Electromagnetic Field (EMF) Method | Measures the electromagnetic field produced by a current flowing through the ground rod system. | Non-destructive, can be used in various soil conditions. | Requires specialized equipment, may not be as precise as other methods. |

Methods for Testing Ground Rod Resistance

Ground rod resistance testing is a critical step in ensuring the safety and effectiveness of electrical grounding systems. Accurate measurements are vital for identifying potential hazards and maintaining the reliability of electrical equipment. Properly installed ground rods provide a low-resistance path for fault currents to flow to the earth, preventing dangerous voltage levels from building up on equipment and protecting personnel.

Speaking of grounding, testing a ground rod is crucial for safety, especially if you’re a DIYer. While I’m getting excited about the upcoming fall tour, lykke li announces fall tour which is amazing, a properly functioning ground rod is paramount. Ultimately, ensuring a safe electrical system is key when you’re working on your home projects, so always double-check the ground rod before you start any work.

This section delves into various methods used to assess the resistance of ground rods.Understanding the methods and procedures for testing ground rod resistance allows for a comprehensive evaluation of the grounding system’s performance. This, in turn, ensures a secure and reliable electrical system.

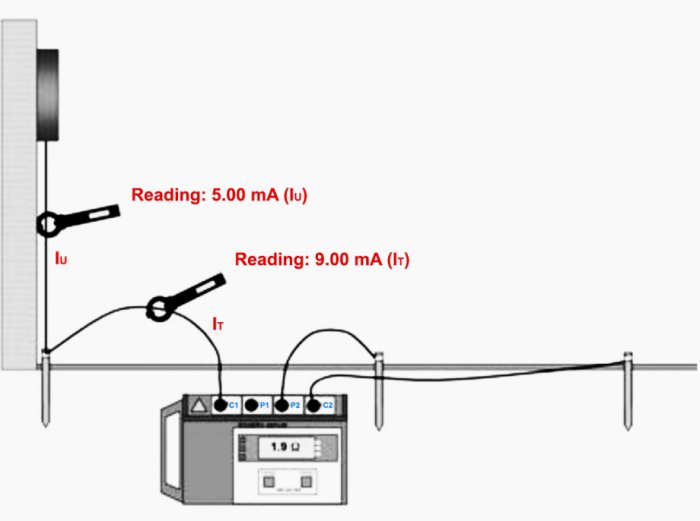

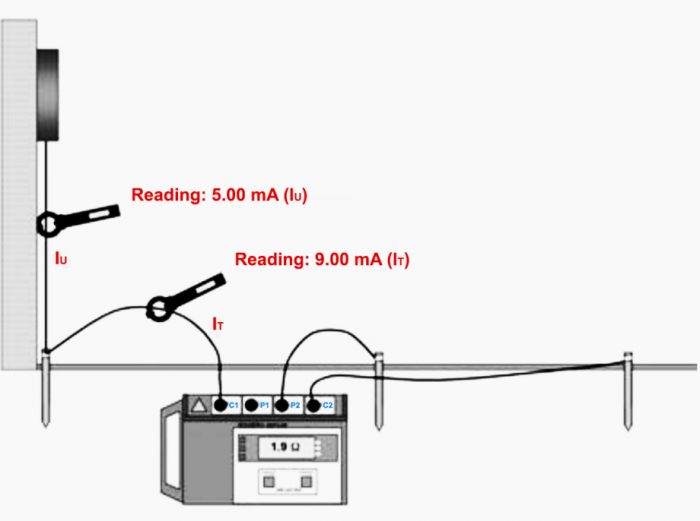

Ground Resistance Tester Methods

Ground resistance testing employs various methods, each with its own advantages and disadvantages. The selection of the appropriate method depends on the specific requirements of the project, including the size of the system and the desired accuracy of the measurement.

Using a Ground Resistance Tester

A ground resistance tester is a specialized instrument used to measure the resistance of a ground rod or grounding system. It typically employs a four-terminal method, minimizing the influence of contact resistance.

- Preparation: Ensure the ground rod is clean and free of debris. Connect the test leads securely to the ground rod and the ground tester terminals. Verify that the test leads are correctly connected.

- Measurement: Turn on the ground resistance tester and follow the manufacturer’s instructions to initiate the measurement process. The tester will typically display the ground rod resistance value on its screen.

- Interpretation: Carefully analyze the measured resistance value. This value should meet the requirements of local electrical codes and safety standards.

- Record Keeping: Document the date, time, location, and measured ground rod resistance. Include any observations or anomalies in the records.

Advantages and Disadvantages of Various Methods

Different methods for ground rod resistance testing offer varying degrees of accuracy and practicality.

- Wenner Method: This method, utilizing a four-electrode configuration, provides a good approximation of the ground resistance. Its advantage lies in its simplicity and relative ease of use. However, it can be less accurate in complex or uneven soil conditions. It’s often used for preliminary assessments or when high precision is not critical.

- Falling Potential Method: This method involves measuring the time it takes for a voltage drop to reach a specific level. It is more accurate in detecting anomalies in the soil or uneven ground conditions. However, it is generally more complex and time-consuming compared to other methods. It is well-suited for highly accurate ground resistance measurements, especially in areas with highly variable soil conditions.

- The Use of Ground Resistance Tester: Ground resistance testers provide a direct and reliable method for determining the ground rod resistance. They typically use the four-terminal method to minimize the impact of contact resistance. This method is quite accurate and relatively quick. However, the cost of the equipment can be a factor. Furthermore, proper calibration and maintenance of the tester are essential to ensure accurate readings.

Summary Table of Ground Rod Testing Methods

| Method | Equipment | Typical Resistance Readings (Ω) | Advantages | Disadvantages |

|---|---|---|---|---|

| Wenner | 4 electrodes, meter | 0.5-100+ | Simple, relatively inexpensive | Less accurate in complex soil conditions |

| Falling Potential | 2 electrodes, timer, voltmeter | 0.5-100+ | More accurate in uneven soil | More complex, time-consuming |

| Ground Resistance Tester | Ground resistance tester | 0.5-100+ | Accurate, relatively quick | Costly, requires calibration |

Factors Affecting Ground Rod Resistance

Understanding ground rod resistance is crucial for ensuring the safety and reliability of electrical systems. A poorly performing ground rod can lead to hazardous situations and equipment malfunctions. The performance of a ground rod is highly dependent on the surrounding soil conditions, impacting the effectiveness of the grounding system.

Soil Type Influence

Soil composition significantly impacts the resistance of a ground rod. Different soil types have varying degrees of moisture retention and conductivity. This directly affects how well the soil can carry the current. The conductivity of the soil is a key factor in determining the resistance of the ground rod. Different soil types offer different levels of conductivity, thus influencing the overall ground rod resistance.

- Clayey soils generally exhibit higher resistance due to their low moisture content and poor conductivity. The dense structure of clay restricts the flow of current, increasing the overall resistance. This can make it harder to establish a reliable ground connection in clay-rich areas.

- Sandy soils, conversely, tend to have lower resistance. Their loose structure allows for better water infiltration and improved current flow. This results in a lower overall resistance and makes them a more suitable environment for grounding.

- Silty soils often fall between these two extremes. Their resistance is influenced by the amount of moisture present, and the consistency of the soil can significantly impact the conductivity.

Moisture Content Impact

Moisture content plays a critical role in determining soil conductivity and, consequently, ground rod resistance. Water molecules act as charge carriers, facilitating the flow of current through the soil. The more moisture present, the better the conductivity and the lower the resistance. Conversely, dry soil restricts the flow of current, resulting in higher resistance.

- Wet soil offers lower resistance due to the abundance of water molecules facilitating current flow. This improved conductivity leads to a more effective grounding system.

- Dry soil presents higher resistance, hindering the flow of current and making it harder to achieve an adequate grounding system. This can compromise the safety and reliability of electrical equipment.

Soil Condition and Resistance Correlation

The relationship between soil conditions and ground rod resistance is complex. Different soil types react differently to varying moisture levels, affecting their ability to conduct electricity. This table illustrates a general correlation between common soil conditions and typical ground rod resistance values.

| Soil Type | Moisture Content | Typical Resistance (Ω) |

|---|---|---|

| Clayey | Dry | 1000 – 10000 |

| Clayey | Moist | 100 – 1000 |

| Sandy | Dry | 10 – 100 |

| Sandy | Moist | 1 – 10 |

| Silty | Dry | 100 – 1000 |

| Silty | Moist | 10 – 100 |

Note: These values are approximate and can vary based on several factors, including depth of the rod, specific soil composition, and presence of contaminants.

Safety Precautions During Ground Rod Testing

Ground rod testing, while crucial for ensuring electrical safety, carries inherent risks if not performed with meticulous attention to safety protocols. Proper procedures, coupled with the correct personal protective equipment (PPE), are paramount to preventing accidents and maintaining a safe working environment. Understanding potential hazards and implementing mitigation strategies are essential for both the technician and those around them.

Importance of Personal Protective Equipment (PPE)

Adequate personal protective equipment (PPE) is essential for safeguarding against potential hazards during ground rod testing. This includes items like safety glasses, insulated gloves, and sturdy work boots. Proper PPE not only protects against electrical shocks but also shields against physical hazards like falls or debris. The selection and use of PPE should be tailored to the specific risks associated with the testing site and procedures.

Potential Hazards and Mitigation Strategies

Ground rod testing presents several potential hazards. Electrical shock is the most prominent risk, particularly if proper insulation and safety procedures are not followed. The risk of electrical shock can be significantly reduced by adhering to established safety guidelines, using insulated tools, and ensuring proper grounding of the testing equipment. Other hazards include falls from heights, exposure to hazardous materials (if any), and injuries from dropped tools or equipment.

Safe work practices, including proper ladder use, secure footing, and careful handling of tools, can minimize these risks.

Best Practices for Safe Testing Procedures

Ensuring safe testing procedures requires adherence to industry standards and best practices. This includes proper isolation of the testing area, clearly marking the test zone, and ensuring all personnel are aware of the procedures and potential hazards. Communication among the testing team is critical for safe coordination of activities. Regular equipment checks, including verifying the insulation integrity of tools and the proper functioning of safety devices, are crucial for maintaining a safe testing environment.

Furthermore, having a designated safety officer or supervisor present during testing can help ensure proper procedure adherence.

Essential Safety Measures

| Safety Measure | Reason |

|---|---|

| Wearing insulated gloves | Protects against electrical shocks by providing an insulating barrier between the worker and the energized ground rod. |

| Using insulated tools | Prevents electrical contact and reduces the risk of electric shock by isolating the worker from the potentially energized ground rod. |

| Proper grounding of testing equipment | Avoids creating a path for electrical current to flow through the worker’s body. This is essential to prevent electrical shock. |

| Clear marking of test zone | Alerts personnel to the hazardous area, preventing accidental entry or contact with energized equipment. |

| Isolation of the testing area | Creates a controlled environment, limiting exposure to potential hazards and minimizing risks to bystanders. |

| Safety training for personnel | Ensures that all personnel involved understand the risks associated with ground rod testing and know how to implement safe procedures. |

Interpretation of Ground Rod Resistance Results

Understanding the results of a ground rod resistance test is crucial for ensuring the safety and effectiveness of electrical systems. A proper interpretation allows for proactive maintenance, identifying potential issues before they escalate into safety hazards or system failures. Accurate interpretation relies on understanding the acceptable resistance values and how deviations from these standards affect system performance.Interpreting ground rod resistance values involves comparing the measured resistance to established standards and understanding the implications of readings above or below those standards.

This comparison enables a determination of whether the ground rod is performing adequately to protect personnel and equipment from electrical hazards.

Acceptable Resistance Values

Ground rod resistance values vary depending on the specific electrical system and its intended function. The standards for acceptable resistance are established to maintain safety and ensure the system operates effectively. These standards consider factors like the size of the system, the type of equipment, and the soil conditions.

Determining Adequate Ground Rod Performance

A ground rod is considered performing adequately when its resistance falls within the acceptable range for the specific electrical system. This range is established by codes and standards to ensure that the ground fault current is sufficiently low to prevent dangerous voltages. Beyond the measured resistance, other factors like soil conditions, grounding electrode configuration, and system design also influence performance.

Significance of Readings Above or Below Acceptable Range

Readings above the acceptable resistance range indicate potential problems with the ground rod system. This could be due to factors like inadequate rod size, poor soil conductivity, or a compromised connection. Higher resistance readings can result in insufficient ground fault current, increasing the risk of electrical shock.Conversely, readings below the acceptable range are also worthy of attention. While seemingly favorable, excessively low resistance could indicate issues with the system’s design or ground fault current protection.

This could overload the protective devices or lead to other unwanted outcomes.

Ground Rod Resistance Interpretation Table

| Resistance Reading (Ω) | Implication for Ground Rod Performance |

|---|---|

| Below 2.5 Ω | Potentially problematic; low resistance might indicate excessive fault current or a poorly designed system. Further investigation and analysis of the system’s design and protective devices are recommended. |

| 2.5 Ω to 10 Ω | Acceptable for many typical electrical systems. This range typically indicates adequate ground rod performance. |

| 10 Ω to 25 Ω | Potentially marginal; this range might indicate a need for further evaluation. Consider factors like soil conditions and potential issues with the ground rod system. |

| Above 25 Ω | Indicates a significant issue with the ground rod system. This could be due to inadequate rod size, poor soil conductivity, or a poor connection. Further investigation and possible remediation are required to ensure system safety. |

Troubleshooting Ground Rod Issues: Test A Ground Rod

Understanding and addressing ground rod issues is crucial for ensuring electrical safety and system reliability. A high ground rod resistance can indicate a problem with the rod itself, the surrounding soil, or even the connection points. This section delves into common causes, troubleshooting techniques, and solutions to rectify these issues.

Identifying Ground Rod Problems Based on Resistance Readings

High ground rod resistance readings often signal a problem. A resistance reading significantly higher than the expected value for the specific site conditions suggests potential issues. This elevated resistance can stem from various factors, which need careful examination. Analyzing the specific reading and correlating it with site characteristics is essential for pinpointing the cause.

Causes of High Ground Rod Resistance, Test a Ground Rod

Several factors can contribute to high ground rod resistance. Poor soil conditions are a primary culprit. Clayey, rocky, or dry soils offer higher resistance to current flow. Similarly, the presence of waterlogged areas, particularly with high salt content, can also affect the resistance. Inadequate rod length or poor contact between the rod and the surrounding soil also contribute to elevated resistance.

Corrosion on the rod surface and/or poor connections at the rod-to-cable joint further exacerbate the issue. Other contributing factors include buried objects interfering with the ground current flow.

Solutions for Addressing Ground Rod Issues

Various solutions can address ground rod problems, depending on the root cause. For poor soil conditions, improving soil conductivity is a common approach. This could involve the addition of conductive soil amendments, such as conductive additives or soil-improving agents. Similarly, extending the rod length is a remedy for insufficient rod length. A longer rod can improve the contact area with the ground, thus reducing resistance.

Proper soil compaction around the rod can also improve the contact. Corrosion on the rod can be addressed through the use of corrosion-resistant materials or coatings. In cases of buried obstructions, the obstruction should be removed or bypassed. If the connection is poor, ensure proper connections are made at all points, and check for corrosion.

Rectifying Issues with Poor Soil Conditions

Soil conditions are a critical factor in ground rod resistance. For instance, if the soil is highly resistive, using conductive soil amendments can dramatically improve the ground rod’s performance. This involves introducing materials that increase the soil’s conductivity, enabling better current flow. The specific amendment and the amount required depend on the soil type and the desired level of conductivity.

Alternatively, if the soil is waterlogged, drainage solutions may be necessary to improve the overall soil conductivity.

Rectifying Issues with Inadequate Rod Length

Insufficient rod length is another significant contributor to high resistance. Extending the rod length provides a larger surface area for current flow, thus lowering the overall resistance. This can be done by driving the rod deeper into the ground or installing additional rods. The extent of extension required depends on the specific site conditions and the desired resistance level.

Table of Common Ground Rod Problems and Solutions

| Ground Rod Problem | Potential Solutions |

|---|---|

| Poor Soil Conductivity (e.g., dry, rocky soil) | Adding conductive soil amendments, improving soil compaction, or drainage solutions. |

| Inadequate Rod Length | Extending the rod length or installing additional rods. |

| Corrosion on the Rod | Using corrosion-resistant materials or coatings. |

| Poor Connections (e.g., at rod-to-cable joint) | Ensuring proper connections and checking for corrosion. |

| Buried Obstructions | Removing or bypassing the obstruction. |

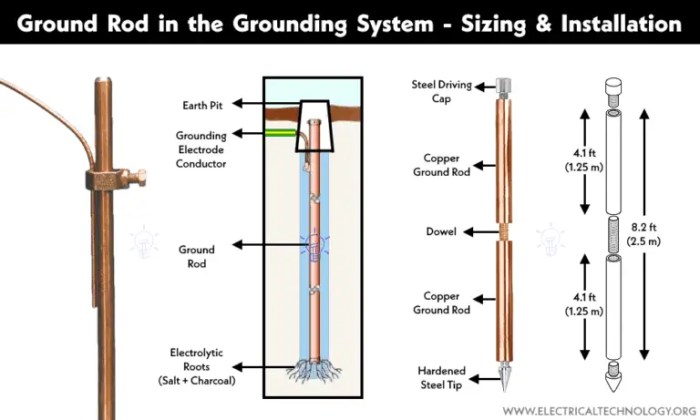

Ground Rod Installation and Maintenance

Proper ground rod installation is critical for the safety and effectiveness of electrical systems. A poorly installed or maintained ground rod can lead to dangerous voltage fluctuations, equipment damage, and even electrical hazards. A well-maintained ground rod system ensures reliable grounding, reducing the risk of electrical shock and protecting sensitive equipment.A correctly installed ground rod provides a low-impedance path for fault currents to flow safely into the earth.

Testing a ground rod is crucial for electrical safety, just like understanding how to keep an Alpha Male Interested requires careful consideration. Knowing how to properly test a ground rod ensures your system is working correctly, and understanding how to maintain a strong connection, like the ones described in Keep an Alpha Male Interested , can be a valuable lesson in the broader context of electrical grounding.

A good ground rod is essential for preventing electrical hazards, and a good relationship foundation can be established with similar careful attention to detail.

This is vital for protecting personnel and equipment connected to the system. Consistent maintenance ensures the ground rod system continues to function effectively, avoiding costly repairs and potential safety incidents.

Importance of Proper Ground Rod Installation

A properly installed ground rod is fundamental to a safe and reliable electrical system. This ensures that fault currents are efficiently conducted into the earth, minimizing the risk of electrical shocks and equipment damage. The installation process must follow specific guidelines and best practices to achieve optimal performance.

Steps Involved in Installing a Ground Rod Correctly

Correct installation is essential to achieve a robust grounding system. The process typically involves the following steps:

- Site Preparation: Excavate a suitable hole of appropriate depth and width, ensuring the ground rod can be securely inserted. Consider soil conditions, ensuring the rod is not placed in a water-saturated area. This initial step is crucial to the effectiveness of the entire installation.

- Rod Insertion: Carefully insert the ground rod into the prepared hole, ensuring it is vertical and straight. Use a suitable tool or method to maintain the rod’s vertical alignment. Correct insertion is critical for proper electrical conductivity.

- Rod Connection: Securely connect the ground rod to the grounding system using appropriate grounding clamps and connectors. Proper connection is essential for establishing a low-resistance path to the earth. Ensure all connections are tight and free of corrosion.

- Backfilling: Fill the hole with compacted backfill material. The backfill should be carefully compacted to ensure there are no voids around the rod. Compaction is vital for maintaining the rod’s position and conductivity.

- Grounding Electrode Conductor Connection: Connect the grounding electrode conductor to the ground rod, ensuring a secure connection. The grounding electrode conductor (GEC) must be properly sized to carry the expected fault current.

Importance of Regular Ground Rod Maintenance

Regular maintenance is crucial for maintaining the integrity and effectiveness of the ground rod system. This prevents issues from arising and ensures the system continues to function reliably over time.

Step-by-Step Procedure for Ground Rod Maintenance

Regular maintenance can prevent future issues and maintain the safety and efficiency of your grounding system.

Testing a ground rod is crucial for electrical safety, but sometimes it’s fun to delve into other topics. For example, I’ve been listening to the amazing Wilco detail alpha mike foxtrot rarities box set whats your 20 greatest hits collection lately here. While I’m enjoying the deep cuts, I still need to get back to checking the ground rod connections to ensure my electrical system is reliable and safe.

Ultimately, a proper ground rod test is key for peace of mind.

- Visual Inspection: Inspect the ground rod for any signs of damage, corrosion, or loose connections. Look for any changes in the rod’s position or the surrounding ground. This initial inspection can identify potential problems before they escalate.

- Resistance Testing: Measure the ground resistance to ensure it remains within acceptable limits. This testing method is crucial for evaluating the ground rod’s performance and identifying any degradation in conductivity.

- Cleaning: Clean any corrosion or debris from the ground rod and its connections. Proper cleaning is vital to maintain the ground rod’s conductivity.

- Connection Tightening: Tighten any loose connections between the ground rod and the grounding system. Loose connections can increase resistance and decrease the efficiency of the grounding system.

- Backfill Inspection: Inspect the backfill around the ground rod for any signs of settling or damage. Ensure the backfill maintains the rod’s position and integrity. The integrity of the backfill is critical for long-term stability.

Recommended Maintenance Schedule

The following table summarizes the recommended maintenance schedule for different ground rod systems:

| Ground Rod System | Annual Maintenance | Periodic Maintenance (Every 3-5 years) |

|---|---|---|

| Residential | Visual inspection, resistance test | Deep excavation and rod inspection, re-grounding |

| Commercial | Visual inspection, resistance test, cleaning | Deep excavation and rod inspection, re-grounding, connection tightening |

| Industrial | Visual inspection, resistance test, cleaning, connection tightening | Deep excavation and rod inspection, re-grounding, connection tightening, and corrosion treatment |

Examples of Ground Rod Systems

Ground rods are a fundamental component of electrical grounding systems, providing a low-impedance path for fault currents to flow into the earth. The specific design of a ground rod system depends heavily on the application’s electrical characteristics, soil conditions, and safety requirements. Understanding the various types and their suitability is crucial for effective grounding.Grounding systems are not a one-size-fits-all solution.

Different electrical systems, from residential homes to large industrial facilities, demand unique grounding strategies. The chosen system must effectively dissipate fault currents, minimizing the risk of electrical shocks and equipment damage.

Ground Rod System Types

Various ground rod systems are employed based on the specific needs of the application. Understanding these systems and their characteristics helps in selecting the most appropriate solution for a particular situation.

- Single Ground Rod Systems: These systems typically consist of a single ground rod driven into the earth. While simple, they may not be sufficient for large or complex electrical systems, especially in locations with high fault current potential or poor soil conductivity.

- Multiple Ground Rod Systems: This approach involves multiple ground rods interconnected to create a larger, more effective ground plane. This is often necessary for applications with substantial fault currents or extensive electrical equipment, as the interconnected rods distribute the fault current more evenly.

- Ground Grid Systems: A ground grid involves a network of interconnected conductive materials, like metal plates or wires, buried in the earth. Ground grids provide a broad, low-resistance surface area for current dissipation, making them ideal for high-power electrical systems and those with significant fault current potential. Their larger surface area enhances conductivity and effectiveness compared to single or multiple ground rods.

- Combination Ground Rod Systems: These systems often incorporate elements of single, multiple, and/or ground grid systems. They’re used in situations where the characteristics of different areas of the electrical system necessitate tailored grounding approaches. For example, a combination system might use a ground grid for high-voltage equipment and multiple ground rods for smaller, low-voltage systems.

Factors Influencing Ground Rod System Selection

The appropriate ground rod system depends on several key factors. Careful consideration of these factors ensures a robust and effective grounding solution.

- Soil Conductivity: The ability of the soil to conduct electricity directly impacts the effectiveness of the ground rod system. Highly conductive soils (e.g., moist clay) allow for better current dissipation compared to less conductive soils (e.g., dry sand).

- Fault Current Potential: The anticipated magnitude of fault currents in the electrical system plays a crucial role in ground rod system selection. Systems with higher fault current potential require a larger ground plane or multiple ground rods to handle the current effectively.

- Electrical System Capacity: The size and complexity of the electrical system determine the necessary grounding capacity. Large industrial systems may demand a ground grid, while residential systems might suffice with a single ground rod.

- Environmental Conditions: Factors like moisture content and the presence of conductive minerals in the soil can influence the system’s performance. Specific conditions may necessitate a specialized grounding system design.

Ground Rod System Comparison Table

This table summarizes the key characteristics of different ground rod systems and their suitability for various applications.

| Ground Rod System Type | Description | Suitability for | Advantages | Disadvantages |

|---|---|---|---|---|

| Single Ground Rod | One ground rod | Small electrical systems, residential applications | Simple, cost-effective | Limited capacity, may not be sufficient for high fault currents |

| Multiple Ground Rods | Multiple interconnected rods | Medium-sized electrical systems, commercial applications | Increased capacity compared to single rods | Higher cost than single rods, installation complexity |

| Ground Grid | Interconnected network of conductive materials | Large electrical systems, industrial applications | High capacity, effective current dissipation | Complex installation, high cost |

| Combination System | Hybrid approach combining different systems | Systems with diverse electrical requirements | Tailored to specific needs, efficient | Installation complexity, potential for increased cost |

Last Word

In conclusion, testing a ground rod is a multifaceted process that requires careful consideration of various factors, from soil conditions to safety precautions. This guide has provided a comprehensive overview of the process, from installation and maintenance to troubleshooting common issues. By following the steps Artikeld here, you can ensure the safety and reliability of your electrical systems.

Remember, a well-maintained ground rod system is an essential element of a safe electrical infrastructure.