Build Your Own Air Conditioner: This comprehensive guide delves into the exciting world of DIY air conditioning, exploring everything from evaporative coolers to refrigeration-based systems. We’ll cover the potential benefits and drawbacks, necessary resources, and safety precautions. Prepare to dive into the intricacies of designing, constructing, and maintaining your own personalized cooling solution.

From basic schematics and material selection to troubleshooting potential issues, we’ll provide a practical and detailed approach. Learn about the pros and cons of different systems, and discover how to tailor your design to your specific needs and budget. Get ready to cool things down, literally!

Introduction to DIY Air Conditioning

Building your own air conditioning system can be a rewarding project, offering potential cost savings and a deeper understanding of how these systems work. However, it also presents significant challenges, requiring careful planning, precise execution, and a thorough understanding of the potential hazards involved. Successfully tackling a DIY air conditioning project often hinges on a comprehensive grasp of the different types of systems, the necessary resources, and the inherent risks.This guide explores the various avenues for creating a DIY air conditioning solution, highlighting the benefits and drawbacks of each approach.

It delves into the specific materials, tools, and safety precautions essential for each system type, enabling a more informed decision-making process. We will cover evaporative coolers, DIY swamp coolers, and refrigeration-based systems, providing a comprehensive comparison of their pros and cons.

Types of DIY Air Conditioning Systems

DIY air conditioning systems broadly fall into two categories: evaporative cooling and refrigeration-based cooling. Each approach has its own set of advantages and disadvantages.

Evaporative Coolers

Evaporative coolers, also known as swamp coolers, are a simpler and often more cost-effective DIY option. They rely on the evaporation of water to cool the air. The process of water evaporation absorbs heat from the surrounding environment, resulting in a decrease in air temperature.

- These systems typically involve a water reservoir, a fan, and a system of baffles or pads to facilitate water evaporation. They are relatively straightforward to build, with many readily available DIY tutorials available online.

- Essential materials include a water tank, a fan, a porous material (like wood fiber or fabric), and piping or tubing to channel water. Tools needed may include saws, drills, and measuring equipment.

- Evaporative coolers are generally less complex to construct than refrigeration-based systems. They require less specialized equipment and are often more accessible to individuals with a basic understanding of home improvement.

Refrigeration-based Systems

Refrigeration-based systems, while more complex, offer a potential for greater cooling capacity and control. These systems leverage the principles of thermodynamics, using a refrigerant to absorb heat and transfer it to the outside air.

- Building a DIY refrigeration-based system requires a deeper understanding of refrigeration cycles and components, including compressors, condensers, evaporators, and expansion valves. Detailed knowledge of safety protocols is crucial due to the use of refrigerants.

- Necessary resources encompass compressors, refrigerants (with strict adherence to safety regulations), tubing, and specialized fittings. The tools needed are more sophisticated, potentially including specialized tools for working with refrigerant lines and compressors.

- While offering potentially greater cooling power, these systems present a greater risk of safety issues and require a more advanced skill set compared to evaporative coolers.

Safety Considerations

Safety is paramount in any DIY project, especially when dealing with potentially hazardous materials or equipment. Care must be taken to avoid injuries and ensure compliance with safety regulations.

Building your own air conditioner can be surprisingly rewarding, but sometimes you just need a little chill in your life. Speaking of chill, have you heard about the new Charli XCX Valentine? This new track is seriously giving me some serious inspiration for my DIY AC project. Hopefully, with a little more research, I can get my own air conditioning unit up and running soon!

- Working with refrigerants requires strict adherence to safety protocols. Improper handling can lead to serious health risks. Always consult safety data sheets (SDS) for specific refrigerants and follow local regulations regarding refrigerant disposal.

- Electrical components must be installed and maintained correctly to avoid electrical hazards. Ensure proper grounding and insulation to prevent short circuits or shocks.

- Proper ventilation and protective equipment should be used throughout the project to minimize exposure to potential contaminants.

Comparison of DIY Air Conditioning Systems

| System Type | Pros | Cons | Complexity |

|---|---|---|---|

| Evaporative Cooler | Relatively inexpensive, easy to construct, effective for mild climates | Limited cooling capacity, may not be effective in hot or humid climates, requires water source | Low |

| Refrigeration-based System | Higher cooling capacity, better control over temperature, potentially suitable for diverse climates | Higher cost, more complex construction, potential safety hazards associated with refrigerants | High |

Design and Planning

Designing a DIY air conditioning system requires careful planning and consideration of various factors. A well-thought-out design ensures the system is efficient, effective, and meets the specific needs of the space it will cool. This section will detail the crucial aspects of design and planning, including schematic diagrams, materials, tools, and a step-by-step guide.

Basic Schematic Diagram

A basic schematic diagram visually represents the flow of the DIY air conditioning system. It illustrates the key components and their interconnections, making the design easier to understand and implement. This diagram helps in visualizing the refrigerant flow, air movement, and the function of each component.

Example of a basic schematic diagram: A simplified schematic might show a compressor connected to a condenser, which in turn connects to an evaporator. The evaporator would be situated in the area needing cooling, and a fan would circulate the cooled air. Connecting pipes would show the refrigerant’s path. Labels would identify each component (e.g., compressor, condenser, evaporator, expansion valve).

Factors to Consider, Build Your Own Air Conditioner

Several factors significantly influence the design and effectiveness of a DIY air conditioning system. Understanding these factors is crucial for a successful project.

Ever fancied building your own air conditioner? It’s surprisingly doable, requiring some technical know-how and a good understanding of thermodynamics. Diving into a project like this can be quite rewarding, but remember to consider the complexities involved, like the intricacies of bing ruth no home of the mind when dealing with the many factors at play.

Ultimately, building your own air conditioner is a fascinating challenge for those seeking a unique cooling solution.

- Climate: The local climate significantly impacts the design. Areas with high humidity may require a dehumidification system, while areas with extremely high temperatures may necessitate a more robust cooling capacity. For example, a system designed for a dry, hot desert climate will differ from one designed for a humid subtropical region.

- Budget: The budget directly influences the choice of materials, components, and the complexity of the system. A more complex system with higher-quality components will likely cost more. Careful cost analysis and prioritization of needs are essential.

- Space: The available space dictates the size and layout of the system. Sufficient space is needed for the components, installation, and maintenance. Consider the space needed for the condenser unit and any ductwork required for air distribution.

- Energy Efficiency: The energy efficiency of the system is crucial. Choosing energy-efficient components, such as high-efficiency compressors and insulation, can minimize operational costs over time. A well-insulated system and strategically placed vents contribute to greater energy efficiency.

Suitable Materials

Choosing the right materials is critical for the performance and longevity of the DIY air conditioning system. Materials must withstand the operating conditions and have the necessary properties.

- Refrigerant: Selecting the correct type of refrigerant is essential. It should be environmentally friendly and compatible with the components. R-22 is a widely used refrigerant but is being phased out due to environmental concerns.

- Pipes and Tubing: Copper tubing is commonly used for its durability and conductivity. Other materials like PVC might be suitable for specific applications, but copper is generally favored.

- Insulation: Insulation materials prevent heat transfer and maintain the temperature difference between the inside and outside of the system. Appropriate insulation materials are crucial to achieving efficiency.

- Electrical Components: The choice of electrical components (wiring, switches, fuses) must adhere to local electrical codes. Over-sized wiring or incorrect fuses can lead to safety hazards and system malfunctions.

Required Tools

Having the right tools is essential for a successful DIY project. This list includes tools needed for various aspects of the project, from initial design to final installation.

- Measuring tools: Measuring tapes, rulers, and levels are crucial for accurate measurements and installations.

- Plumbing tools: Wrenches, pipe cutters, and soldering equipment (if applicable) are needed for pipe connections.

- Electrical tools: Screwdrivers, wire strippers, and crimpers are required for electrical connections.

- Safety equipment: Safety glasses, gloves, and appropriate clothing are vital for personal protection.

Step-by-Step Design Guide

| Step | Action | Materials | Tools |

|---|---|---|---|

| 1 | Determine the size and location of the cooling unit, considering the space available and the climate. | Space dimensions, climate data | Measuring tape, ruler, level |

| 2 | Select suitable components, including refrigerant, pipes, insulation, and electrical components, based on the design and budget. | Refrigerant, pipes, insulation, wiring, switches, fuses | Catalogs, online resources, electrical schematics |

| 3 | Create a detailed schematic diagram of the system, including all connections and components. | Paper, drawing tools, components list | Pencil, ruler, protractor, drafting tools |

| 4 | Calculate the required cooling capacity based on the size of the space and the local climate. | Climate data, space dimensions | Calculator, online tools |

Construction Methods: Build Your Own Air Conditioner

Building your own air conditioning system is a rewarding project, but careful construction is crucial. Proper materials and techniques ensure efficient cooling and long-term performance. This section dives into the practical aspects of building various components and addresses essential safety considerations.Different construction methods are available for each component of a DIY air conditioning system. Choosing the right method depends on factors like budget, desired efficiency, and available tools and skills.

Understanding these options allows you to make informed decisions throughout the entire building process.

Evaporator Coil Construction

Copper tubing, often used for its excellent thermal conductivity, is a common material for evaporator coils. A coiled configuration maximizes surface area for heat exchange. This setup is typically soldered to create a leak-proof system, ensuring proper refrigerant flow. Alternatively, pre-fabricated evaporator coils are available, reducing the construction time and complexity, though often at a higher cost.

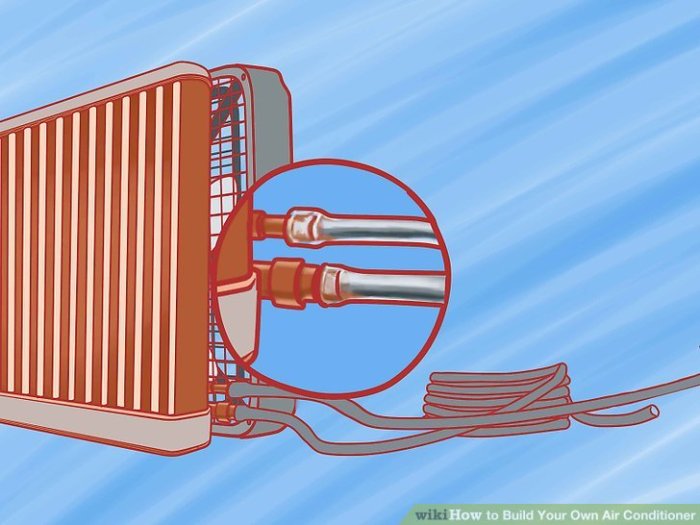

Condenser Coil Construction

Aluminum or copper coils are suitable for condenser coils. The larger surface area compared to the evaporator facilitates efficient heat rejection. For DIY systems, carefully measuring and cutting the coil to the necessary length is vital. The condenser coils are often mounted on a frame for structural support and optimal airflow.

Ductwork Construction

Ductwork is essential for directing airflow throughout the house. Insulated metal ductwork offers better efficiency than non-insulated options. Consider using flexible ductwork for easily maneuvering around obstacles in your home. Measure the ductwork carefully to ensure it matches the air handler and vents. Securely attaching ductwork with appropriate fasteners is critical to prevent leaks and ensure proper airflow.

Insulation Methods

Proper insulation minimizes heat transfer, which directly impacts the system’s efficiency. Fiberglass insulation is a common choice for its affordability and effectiveness. Spray foam insulation provides a higher level of insulation but requires specialized application. The selection of insulation material should consider the desired level of efficiency and the potential for environmental impact.

| Insulation Material | Pros | Cons |

|---|---|---|

| Fiberglass | Affordable, readily available | Can be dusty to work with, less effective than spray foam |

| Spray Foam | High R-value, airtight seal | Specialized application, potentially higher cost |

Component Assembly

Assembling the components of your DIY air conditioner involves precise steps. First, securely attach the evaporator coil to the refrigerant lines. Next, install the condenser coil, ensuring proper airflow around it. Connecting the refrigerant lines to the compressor is crucial, and the installation of the ductwork completes the airflow system. Proper sealing of all connections is paramount to prevent refrigerant leaks and maintain efficiency.

A leak in the refrigerant system can significantly reduce the efficiency of your DIY air conditioning system. Regular checks and proper sealing are crucial.

Safety Precautions

Working with refrigerants requires caution. Always follow safety guidelines and use appropriate personal protective equipment (PPE). Avoid working in confined spaces without adequate ventilation. Ensure proper handling of electrical components to prevent electrical hazards. Refrigerant leaks can be dangerous; use proper ventilation and safety equipment when handling refrigerants.

Troubleshooting

Troubleshooting potential issues during construction is important. If the system isn’t cooling efficiently, check for leaks in the refrigerant lines and ensure proper airflow through the condenser. A lack of airflow can cause reduced cooling. Verify that the electrical connections are secure.

Operation and Maintenance

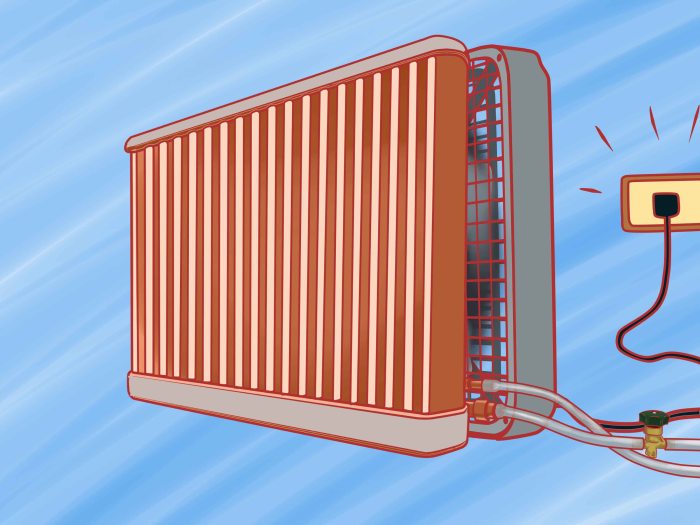

Bringing your DIY air conditioning system to life requires understanding its operational principles and implementing a regular maintenance schedule. Proper operation ensures efficient cooling and a long lifespan for your system. Maintenance prevents breakdowns and optimizes performance, making your home comfortable and energy-efficient.This section details the crucial aspects of operating and maintaining your DIY air conditioning system, from startup procedures to troubleshooting potential issues and energy-saving techniques.

Operation Principles

Your DIY air conditioning system, like any refrigeration cycle, relies on the principles of vapor-compression refrigeration. A refrigerant absorbs heat from the indoor air, vaporizes, and then releases this absorbed heat outdoors. The cycle repeats, constantly moving heat from inside to outside. Understanding this cycle is key to optimizing performance.

Importance of Regular Maintenance

Regular maintenance is crucial for the longevity and efficiency of your DIY air conditioning system. Neglecting maintenance can lead to decreased cooling capacity, increased energy consumption, and premature component failure. A well-maintained system operates more efficiently and quietly, providing long-term comfort.

Starting and Operating the System

A step-by-step guide for starting and operating your DIY air conditioning system is essential.

- Check the refrigerant level. Ensure the correct amount of refrigerant is in the system. Insufficient refrigerant will reduce cooling capacity. Excessive refrigerant can cause compressor overload.

- Verify electrical connections. Confirm all electrical connections are secure and properly insulated. Faulty wiring can lead to electrical hazards and system malfunction.

- Inspect the condensate drain. A clogged condensate drain can cause water to overflow, potentially damaging your home’s interior. Ensure the drain is clear.

- Turn on the power. With all checks completed, turn on the power supply to the system.

- Monitor the cooling output. Observe the cooling performance and adjust settings as needed.

Common Maintenance Tasks

Regular maintenance tasks are vital for preventing problems and maintaining optimal performance.

- Cleaning the condenser coils. Accumulated dust and debris on the condenser coils can significantly reduce the system’s efficiency. Regular cleaning (e.g., monthly) with a brush and compressed air improves heat dissipation.

- Checking and cleaning the evaporator coils. The evaporator coils inside the unit should also be checked and cleaned regularly. This can be done with a vacuum cleaner.

- Inspecting the refrigerant lines. Examine the refrigerant lines for leaks. Refrigerant leaks can lead to reduced cooling capacity and safety hazards.

- Checking the compressor. Inspect the compressor for any unusual sounds or vibrations. Unusual sounds can indicate a potential problem.

- Maintaining the outdoor unit. Ensure adequate airflow around the outdoor unit by removing any obstructions. This will maintain optimal cooling performance.

Potential Problems and Solutions

Addressing potential issues during operation is crucial.

- System not cooling:

- Check the refrigerant level.

- Inspect for leaks.

- Ensure the condenser coils are clean.

- System making unusual noises:

- Check the compressor for damage.

- Inspect the motor for problems.

- Check the refrigerant lines for kinks.

- System leaking water:

- Check the condensate drain for clogs.

- Ensure proper drainage.

Energy-Saving Techniques

Implementing energy-saving techniques can significantly reduce operating costs.

- Use a programmable thermostat. Programmable thermostats allow you to set different temperatures for different times of the day, reducing energy consumption.

- Seal air leaks around windows and doors. Air leaks can significantly reduce the efficiency of your DIY air conditioning system. Sealing these gaps can save energy.

- Install proper insulation. Insulating your home can significantly reduce heat transfer and decrease the load on your air conditioning system.

- Optimize the positioning of the unit. Place the outdoor unit in an area with adequate airflow.

Environmental Impact

Building your own air conditioning system can be a rewarding project, but understanding its environmental footprint is crucial. From the refrigerants used to the materials employed in construction, every aspect of DIY air conditioning has an impact on the environment. Careful consideration of these factors ensures a more sustainable approach.The environmental impact of a DIY air conditioning system encompasses a range of factors, from the energy consumption during operation to the materials used in its construction.

Choosing sustainable materials and refrigerants, and optimizing energy efficiency, are vital for minimizing the overall environmental impact.

Ever thought about building your own air conditioner? It’s a fascinating DIY project, but sometimes you just need a chill vibe, like listening to some tunes. Check out this awesome track, “zed bias trouble in the streets ft mark pritchard” zed bias trouble in the streets ft mark pritchard , to really get that cool feeling going.

Regardless of the source of your chill, building your own AC system is a seriously rewarding project, though! It’s all about the process, right?

Refrigerant Choices and Their Impact

Different refrigerants have varying global warming potentials (GWP). Selecting refrigerants with lower GWP values is crucial for reducing the system’s contribution to climate change. Hydrofluorocarbons (HFCs), while often used in conventional systems, have high GWP values. In contrast, natural refrigerants like ammonia and carbon dioxide have significantly lower GWP. Proper selection and handling of refrigerants are essential to minimize environmental damage.

This careful consideration can significantly reduce the system’s environmental footprint.

Material Sustainability in Construction

The materials used in the construction of a DIY air conditioning system play a crucial role in its overall environmental impact. Using recycled or sustainably sourced materials reduces the demand on natural resources and minimizes waste. For example, opting for reclaimed wood or recycled metals can lessen the environmental impact of the construction process. Consideration of material lifespan and recyclability is also vital for long-term sustainability.

Energy Efficiency and Operational Impact

The energy efficiency of a DIY air conditioning system directly affects its environmental impact. A well-designed and properly maintained system will consume less energy, thereby reducing greenhouse gas emissions. Energy-efficient components, such as high-performance compressors and insulation, can significantly improve the system’s energy efficiency. Proper sealing and maintenance of the system are crucial to avoid leaks, which can lead to increased energy consumption and environmental harm.

Optimizing the system’s operation for the specific climate and usage patterns is also important.

Impact on Local Ecosystems

A DIY air conditioning system can impact local ecosystems in several ways. The energy used to power the system contributes to the emission of greenhouse gases, which can have cascading effects on ecosystems, including temperature changes and shifts in precipitation patterns. The use of certain materials in construction might affect local biodiversity, depending on the extraction and processing methods.

Minimizing the energy consumption of the system is crucial to limit these effects.

Safety Considerations

Building your own air conditioning system is a rewarding project, but it’s crucial to prioritize safety throughout the process. Ignoring safety precautions can lead to serious injuries or property damage. This section Artikels the essential safety measures to follow for a successful and secure DIY air conditioning installation.

Potential Hazards

DIY air conditioning work involves various potential hazards. Working with electricity, refrigerants, and potentially high-pressure components necessitates careful attention to detail. Improper handling of these elements can result in electric shocks, chemical burns, refrigerant leaks, and equipment damage. Furthermore, improper installation can lead to reduced efficiency, performance issues, and even safety risks for the system’s operation.

Safety Procedures and Precautions

Adhering to established safety procedures is paramount. Before starting any work, thoroughly review the manufacturer’s instructions for the equipment and materials being used. Always disconnect power to the electrical components before any work on the system. Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator, especially when working with refrigerants or other chemicals. Proper ventilation is essential when handling refrigerants to prevent inhalation of harmful vapors.

Having a fire extinguisher readily available is crucial, as well as a first-aid kit for immediate treatment of minor injuries.

Safe Handling of Refrigerants and Other Chemicals

Refrigerants, like R-22 and R-410A, are essential components of air conditioning systems. However, they are also potent and potentially hazardous. Always handle refrigerants in a well-ventilated area and avoid skin contact. Use appropriate safety equipment like gloves and safety glasses. Refrigerant leaks can be dangerous and should be addressed immediately by trained professionals.

Proper disposal methods for refrigerants and other chemicals are vital to prevent environmental contamination.

Emergency Procedures

Accidents can happen, even with the best safety precautions. Having clear emergency procedures in place can mitigate potential risks. Familiarize yourself with the location of emergency exits, fire extinguishers, and first-aid supplies. In case of an electrical shock, immediately disconnect the power source and seek medical attention. For refrigerant leaks, evacuate the area and contact a qualified technician.

For fire, activate the building’s fire alarm system and follow evacuation procedures. Know your local emergency response numbers and be prepared to report any incident promptly.

Safe Operation and Maintenance

Regular maintenance is crucial for ensuring the safe and efficient operation of your DIY air conditioning system. Periodically check for leaks in the refrigerant lines and other components. Inspect electrical connections for any signs of damage or wear. Keep the system’s surroundings clean and free from obstructions that could impede airflow. Ensure proper ventilation and avoid overheating the system.

Consult with qualified professionals for any repairs or maintenance tasks that fall outside your expertise.

Closure

In conclusion, building your own air conditioner is a rewarding project that allows for customization and potentially significant energy savings. However, it’s crucial to understand the associated risks and to prioritize safety throughout the process. This guide equips you with the knowledge and tools to make informed decisions, from initial design to final operation. So, are you ready to take on the challenge of crafting your own cooling masterpiece?

Leave a Reply