Do a Ring Test is a critical method for evaluating materials and processes across various industries. This comprehensive guide delves into the intricacies of ring tests, from their fundamental principles to practical applications. We’ll explore the different types of ring tests, the methodology behind their execution, and the significance of data analysis. Understanding these aspects is key to successful quality control and process improvement.

This guide provides a detailed overview of the steps involved in conducting ring tests, including safety precautions, sample preparation, and equipment considerations. It also explores the interpretation of results and how they contribute to decision-making processes in different sectors.

Introduction to Ring Tests

A ring test is a widely used analytical technique employed to assess the presence or absence of a specific substance or property within a sample. It’s a rapid, often qualitative, method frequently utilized in various scientific disciplines, including chemistry, biology, and materials science. The simplicity of the test and its ability to quickly indicate the presence of a target substance makes it a valuable tool for preliminary screening.Ring tests are particularly useful for initial assessments before more complex and time-consuming analyses are undertaken.

Their application areas span from environmental monitoring to medical diagnostics and quality control in industrial settings. They offer a cost-effective approach to identifying potential issues or confirming the presence of specific compounds, aiding in the decision-making process for further investigation.

Definition and Purpose

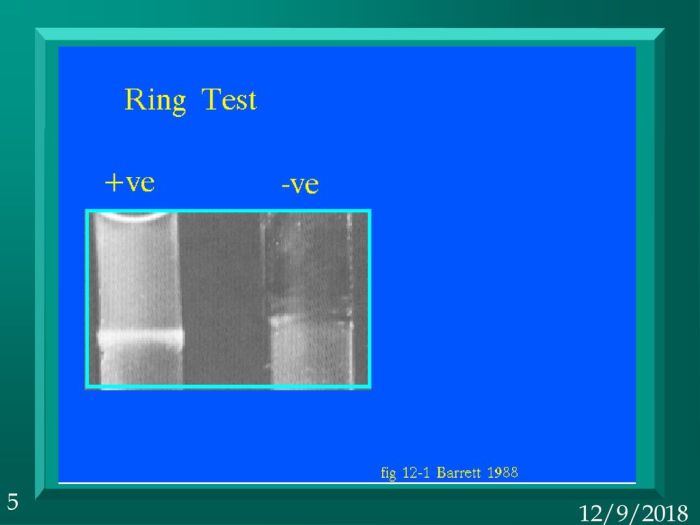

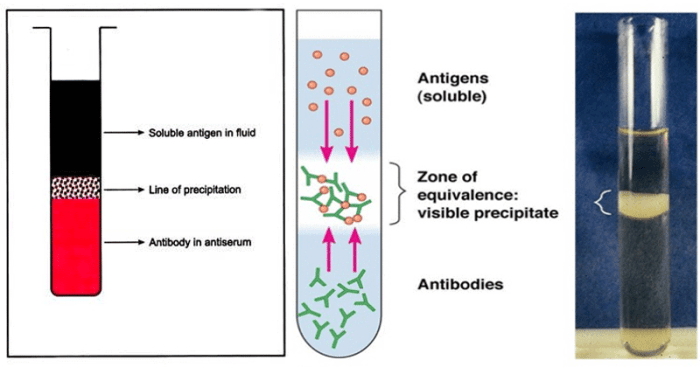

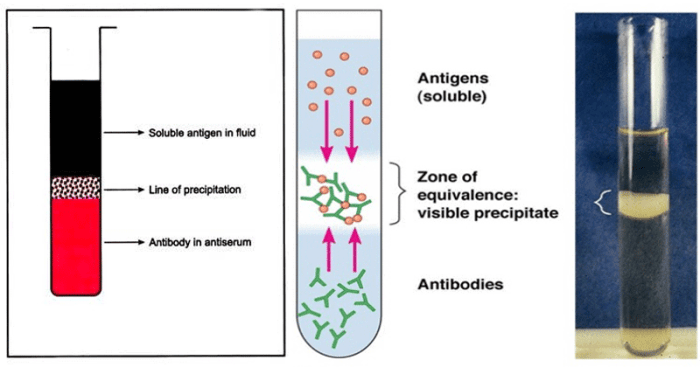

Ring tests are analytical procedures involving the sequential addition of reagents to a sample, where the formation of a colored ring at the interface of the two liquids signals a positive result. This visual indication allows for a quick qualitative assessment of the sample’s composition. The specific purpose of a ring test is to detect the presence or absence of a particular substance or property within a sample.

Key Components

The fundamental components of a ring test generally include:

- The sample: The material or substance being tested. This could be a solution, a solid extract, or a biological sample.

- Reagents: Specific chemical compounds or solutions used to react with the sample and produce a visual change if the target substance is present. The reagents are carefully selected to produce a characteristic reaction with the substance being tested.

- Test tubes or glassware: Suitable containers for conducting the test. The test tubes are typically graduated to allow for precise measurements of reagents.

- Observation tools: Tools like a light source or a color chart might be necessary to clearly observe the color change or the formation of a ring at the interface.

Procedure

A typical ring test procedure typically involves these steps:

- Preparation: The sample and reagents are prepared according to the specific protocol. This includes appropriate dilutions and mixing of the reagents to optimize the reaction.

- Reagent addition: The reagents are added sequentially to the sample in the test tube. The order of addition is crucial and should be followed precisely.

- Observation: The test tube is carefully observed for the formation of a colored ring at the interface between the two layers of liquid (if applicable). The color, intensity, and location of the ring are critical indicators.

- Interpretation: The observed results are compared to known standards to determine if the target substance is present. This interpretation may involve color charts or previously established data.

Examples of Ring Tests

| Test Type | Sample Material | Expected Results | Typical Applications |

|---|---|---|---|

| Ferric Chloride Test | Phenols, certain organic compounds | Formation of a colored ring at the interface | Identifying the presence of phenols in various samples, including water and food products. |

| Ninhydrin Test | Amino acids | Purple or blue ring | Detecting amino acids in biological samples and forensic investigations. |

| Sodium Nitroprusside Test | Cyanide | Purple ring | Identifying cyanide in environmental samples or industrial settings. |

Different Types of Ring Tests

Ring tests are a crucial set of analytical techniques employed to identify and quantify various substances in different samples. They are particularly useful in chemistry, biology, and materials science, providing a quick and often visual means of confirming the presence or absence of specific components. Their simplicity and relatively low cost make them valuable tools in both research and routine laboratory settings.These tests often rely on color changes or the formation of precipitates, which allow for a straightforward interpretation of results.

Different types of ring tests utilize distinct chemical reactions, leading to a variety of observed phenomena. This allows for the categorization and identification of different substances. Understanding the specifics of each type of ring test is essential for proper application and interpretation of the results.

Qualitative Ring Tests

Qualitative ring tests are primarily used to detect the presence or absence of a specific substance. The focus is on observing the qualitative changes, like color change or precipitate formation, to indicate the presence of the target compound. These tests often rely on visual cues, making them relatively easy to perform and interpret.

- The Ferric Chloride Test for Phenols: This test detects the presence of phenols in a sample. A few drops of ferric chloride solution are added to the sample. A characteristic deep violet-colored ring or coloration will indicate the presence of phenols. The intensity of the color can vary depending on the concentration of the phenol present. The reaction occurs due to the formation of a complex between the ferric ion and the phenolic hydroxyl group.

- The Ring Test for Aromatic Aldehydes: This test is designed to detect the presence of aromatic aldehydes. A reagent (such as a solution of 2,4-dinitrophenylhydrazine) is mixed with the sample, and the presence of a distinctive colored ring formation (often orange, red, or yellow) at the interface of the two liquids indicates the presence of the aldehyde. The specific color and intensity of the ring can help to differentiate between different types of aromatic aldehydes.

Quantitative Ring Tests

Quantitative ring tests, in contrast, are designed to measure the concentration of a specific substance. The intensity of the color or the amount of precipitate formed is often correlated with the concentration. These tests typically require more precise measurements and procedures compared to qualitative tests.

- The Biuret Test for Proteins: This test is employed to measure the concentration of proteins in a sample. A solution of copper sulfate in an alkaline environment (e.g., sodium hydroxide) is added to the sample. The presence of peptide bonds in the protein causes a change in color, which can be quantified by comparing the intensity of the color to a known standard.

The intensity of the violet-purple color is directly proportional to the concentration of the protein.

Comparison of Ring Test Methodologies

| Test Name | Principle | Applications | Limitations |

|---|---|---|---|

| Ferric Chloride Test for Phenols | Formation of a colored complex between ferric ion and phenolic hydroxyl group. | Detection of phenols in various samples. | May give false positives with some other compounds. |

| Ring Test for Aromatic Aldehydes | Formation of a colored derivative with a reagent (e.g., 2,4-dinitrophenylhydrazine). | Detection and differentiation of aromatic aldehydes. | The specificity of the test can vary depending on the reagent used. |

| Biuret Test for Proteins | Formation of a colored complex with copper ions in alkaline solution. | Quantitative estimation of protein concentration. | Can be affected by other substances present in the sample. Requires precise measurement of color intensity. |

Methodology and Procedure

Ring tests, a valuable analytical technique, offer a straightforward approach to identifying and quantifying various substances. Understanding the meticulous procedure, encompassing sample preparation, equipment utilization, and result interpretation, is crucial for accurate and reliable results. This section will delve into the detailed methodology, ensuring a comprehensive understanding of the process for diverse ring test applications.

Step-by-Step Procedure for a General Ring Test

A general ring test procedure typically involves mixing specific reagents with a sample solution. The appearance of a colored ring at the interface between the two liquids indicates a positive reaction, signifying the presence of a particular substance. Following the Artikeld steps ensures consistency and reproducibility in the results.

- Safety Precautions: Always wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a lab coat, when handling chemicals. Ensure the workspace is well-ventilated and follow all laboratory safety guidelines. Properly dispose of chemical waste according to established protocols. Thoroughly clean all equipment after each experiment.

- Equipment and Materials: Standard laboratory glassware, including test tubes, graduated cylinders, and beakers, is required. Specific reagents necessary for the test must be prepared and measured accurately. A clean, transparent container or cylinder with a clear base is essential for observation. A stirring rod or magnetic stirrer is optional but often aids in mixing.

- Sample Preparation: The sample solution should be prepared according to the specific instructions for the particular ring test. This may involve dissolving the substance in a suitable solvent, filtering the solution, or adjusting its concentration. Carefully measure and record the volume of the sample solution. The purity and concentration of the sample will impact the accuracy of the results.

- Procedure: Carefully add the reagent to the test tube or container. Slowly layer the sample solution on top of the reagent. The density difference between the sample and the reagent causes them to layer, enabling observation of the color change. Observe the reaction carefully, noting the appearance of any colored rings or precipitates at the interface. Record any observations immediately, including color, intensity, and the presence of any precipitates.

Ever wondered if a Virgo woman is truly interested? Try a “ring test” – subtly dropping hints about your availability and seeing how she responds. This can help you gauge her interest, but remember, it’s just one tool in your arsenal. If you’re noticing a sudden silence from a Virgo, it might be time to consider some of the strategies in What to Do when a Virgo Woman Stops Talking to You , but ultimately, the ring test can help you determine her genuine feelings, giving you valuable insights into her intentions and allowing you to proceed with a better understanding.

Just remember, it’s not always a perfect science, so don’t get overly reliant on just one approach.

Ensure that the layering is smooth, avoiding vigorous mixing that could dilute the reagents or create false positives.

- Result Interpretation: A colored ring at the interface indicates a positive reaction. The color and intensity of the ring can provide qualitative information about the analyte present. Different colors and intensities may correspond to different concentrations. Record your observations accurately, comparing the results to known standards or expected outcomes. Any deviation from the expected result requires careful scrutiny and repeat experiments to ensure accuracy.

Specific Example: Ferric Chloride Test for Phenols

This test identifies the presence of phenols in a sample.

| Material | Procedure Steps | Expected Results |

|---|---|---|

| 0.1M Ferric Chloride Solution | Add a few drops of ferric chloride solution to a test tube. | The solution will turn yellow to orange, depending on the concentration. |

| Sample solution (phenol) | Carefully layer the sample solution on top of the ferric chloride solution. | A reddish-brown ring forms at the interface between the two solutions. |

| Test tube | Observe the solution for any color change or precipitation. | – |

| Distilled Water (optional) | Use distilled water to rinse the test tube to clean any residue. | – |

A positive result is indicated by the formation of a distinct reddish-brown ring at the interface. The absence of a ring suggests the absence of phenols in the sample.

Data Analysis and Interpretation

Ring tests, crucial for assessing the reliability and consistency of analytical methods, demand meticulous data analysis. This phase transforms raw data into meaningful insights, enabling a comprehensive evaluation of the test’s performance. Proper interpretation of these results is paramount for identifying potential errors, validating methodologies, and ultimately, improving the accuracy of analytical procedures.

Data Analysis Techniques

Data analysis in ring tests involves several key steps. First, calculate the mean and standard deviation of each participant’s results. Next, examine the overall variation among the participants’ results, using measures such as the coefficient of variation (CV). This allows for a comprehensive understanding of the reproducibility of the analytical method.

Graphical Representations

Visualizing data enhances comprehension. Histograms can effectively display the distribution of results, helping identify any unusual patterns or outliers. Box plots are another valuable tool, highlighting the median, quartiles, and potential outliers in the data. Scatter plots can show the relationship between different measurements, facilitating the identification of correlations or trends.

Significance of Different Results

Different results from ring tests hold varying significance. High variability among participants often indicates methodological issues, potentially stemming from inadequate training, incorrect instrument calibration, or variations in sample preparation. Conversely, low variability suggests a robust and reliable method, suitable for widespread application.

Interpreting Results in Different Scenarios

Consider a scenario where participants’ results exhibit a significant bias. This might suggest a systematic error within the analytical procedure, requiring further investigation and refinement. Alternatively, if the results display high variability without a clear bias, the method may lack precision. This could necessitate additional training for participants or improvements in the analytical protocol.

Example Interpretations

Imagine a ring test for determining the concentration of a certain chemical in water samples. If the results from different participants cluster closely around the true value, it suggests the method is reliable. However, if the results show a systematic overestimation, a bias in the measurement procedure might be present.

Table of Ring Test Results and Interpretations

| Ring Test Result | Interpretation |

|---|---|

| Low variability, results clustered around true value | Method is reliable and precise. |

| High variability, results widely dispersed | Method lacks precision and requires improvement. |

| Results consistently higher or lower than true value | Systematic bias in the method. |

| Outliers present | Potential errors in data collection or analysis by one or more participants. |

Applications and Examples

Ring tests, a versatile analytical technique, find applications across diverse industries and fields. Their ability to identify and quantify specific substances or properties makes them invaluable in quality control, research, and various other processes. From ensuring food safety to monitoring industrial processes, ring tests offer a rapid and often cost-effective way to achieve valuable insights.This section will delve into the practical applications of ring tests, showcasing real-world examples and explaining how results are interpreted and utilized in decision-making.

We’ll also examine the critical role ring tests play in maintaining quality control standards across various sectors.

Industrial Applications

Ring tests play a crucial role in industrial settings, facilitating quick assessments of raw materials, intermediate products, and finished goods. This rapid analysis allows for timely adjustments in manufacturing processes and minimizes waste.

- Metal Processing: Ring tests can detect the presence of impurities in metal alloys. For example, a ring test can quickly identify the presence of lead in brass, enabling manufacturers to adjust their processes and avoid producing defective products. The presence of specific contaminants can be detected in various materials like iron, steel, and aluminum alloys, leading to effective material sorting and processing.

- Chemical Manufacturing: In chemical manufacturing, ring tests are employed to monitor the purity of reactants and intermediates. For instance, a ring test for a specific chemical can quickly determine if a batch of reactants meets the required purity standards, preventing contamination issues in downstream processes. Real-world examples include ensuring the purity of reagents used in pharmaceutical manufacturing, thereby contributing to product safety.

- Water Treatment: Ring tests are valuable tools in water treatment plants for detecting the presence of specific contaminants. A ring test can be used to assess the presence of heavy metals in water sources, allowing for prompt remedial action. This can help ensure water quality meets standards for human consumption and environmental protection.

Applications in Food Safety and Quality Control

Ring tests are widely used in food analysis to ensure safety and maintain product quality. Their rapid and straightforward nature allows for on-site testing and quick decision-making.

- Food Additives: Ring tests can identify the presence of certain food additives or contaminants. For example, the presence of sulfites in wine can be determined using a ring test, which allows for immediate compliance with food safety regulations.

- Food Spoilage: Ring tests can indicate the presence of certain spoilage agents. A specific ring test can detect the presence of bacteria or other contaminants that can lead to food spoilage, allowing for swift intervention and preventing foodborne illnesses.

- Nutritional Assessment: In some cases, ring tests can be adapted to estimate the presence of certain nutrients in food. For instance, ring tests can provide a preliminary assessment of the amount of Vitamin C in a fruit sample, offering a rapid evaluation.

Ring Test Results and Decision Making

The results of ring tests are instrumental in various decision-making processes. A positive or negative result can guide choices regarding further testing, product handling, and quality assurance procedures.

| Application | Specific Information Obtained |

|---|---|

| Metal Processing | Presence of specific impurities in metal alloys |

| Chemical Manufacturing | Purity of reactants and intermediates |

| Water Treatment | Presence of contaminants in water sources |

| Food Safety | Presence of food additives, spoilage agents, or specific nutrients |

Safety Considerations

Ring tests, while valuable analytical tools, can present potential hazards if not handled with meticulous care. Understanding the potential risks and implementing appropriate safety precautions is paramount to ensure a safe working environment and prevent accidents. Proper training and adherence to established safety protocols are crucial for minimizing risks and maintaining a high level of safety during the entire process.Careful consideration of potential hazards and implementation of preventative measures are essential for safe execution of ring tests.

Adhering to safety protocols and using the appropriate personal protective equipment (PPE) is critical to minimize risks and maintain a secure laboratory environment.

Potential Hazards

Ring tests, like any laboratory procedure, involve handling various chemicals and equipment. Potential hazards include chemical exposure, equipment malfunctions, and improper handling of samples. The specific hazards vary depending on the type of ring test being performed and the materials involved. For example, certain reagents used in precipitation ring tests may be corrosive or toxic, necessitating careful handling and appropriate personal protective measures.

Safety Guidelines and Precautions

Safe laboratory practices are essential to prevent accidents and minimize risks. These practices encompass proper handling of chemicals, equipment, and samples, and they include the use of appropriate personal protective equipment (PPE). Specific safety precautions for different ring tests will be Artikeld in the following section. Adherence to these guidelines and precautions is crucial for a safe and effective laboratory environment.

Importance of Proper Handling of Equipment and Materials

Proper handling of equipment and materials is critical for minimizing risks. This includes inspecting equipment for damage before use, ensuring proper storage of chemicals, and adhering to the manufacturer’s instructions for operating equipment. The use of appropriate containers and handling techniques for different reagents and samples is essential to prevent spills and accidental exposure.

Doing a ring test is a pretty straightforward process, but sometimes it can be tricky to get the perfect result. While you’re working on your ring test, why not treat yourself to a new listen? Check out Mac DeMarco’s latest track, “All of Our Yesterdays” listen to mac demarcos new song all of our yesterdays. The mellow vibes might just help you focus and get that ring test spot on.

Hopefully, a little musical inspiration will help you perfect your ring test technique!

Emergency Procedures

Having established emergency procedures in place is crucial for mitigating the impact of accidents. These procedures should include clear instructions for handling spills, exposure incidents, and other potential emergencies. Knowing how to react quickly and effectively in case of an accident can minimize harm and facilitate prompt medical attention. Training personnel on emergency procedures is vital for their effective implementation.

Safety Precautions for Different Ring Test Types

- Precipitation Ring Tests: These tests often involve corrosive or toxic reagents. Use appropriate personal protective equipment (PPE), including gloves, goggles, and a lab coat. Perform the test in a well-ventilated area. Always add the reagent dropwise to the sample and avoid direct contact with the skin. Thoroughly clean up any spills immediately using appropriate safety procedures.

Ensure proper disposal of waste materials according to established protocols.

- Colorimetric Ring Tests: These tests often involve colored reagents or indicators. Similar to precipitation tests, use appropriate PPE, work in a well-ventilated area, and handle reagents carefully. Note any unusual color changes or reactions and follow instructions for cleanup and disposal.

- Chromatographic Ring Tests: These tests may involve the use of volatile solvents or high-pressure systems. Use appropriate PPE and ensure proper ventilation to avoid inhalation hazards. Be mindful of the potential for equipment malfunction, such as leaks or pressure surges, and have proper safety measures in place. Follow the instructions for the chromatographic equipment carefully.

Personal Protective Equipment (PPE) Requirements

Appropriate PPE is critical for protecting personnel from potential hazards during ring tests. The specific PPE requirements will depend on the type of test and the materials being used. Essential PPE may include gloves, goggles, lab coats, and respirators. The selection and use of PPE must comply with established safety regulations and procedures.

Case Studies and Practical Applications

Ring tests, a seemingly simple technique, offer powerful insights into diverse fields. From ensuring the quality of manufacturing processes to identifying subtle changes in environmental conditions, ring tests provide a robust and often cost-effective method for problem-solving. This section delves into real-world scenarios where ring tests have proven invaluable, highlighting their impact and applications.Practical application of ring tests spans a wide range of industries.

Doing a ring test is a pretty straightforward process, but it’s important to get it right. Speaking of straightforward, you absolutely have to check out the new Sofia Coppola movie, “On the Rocks,” starring Rashida Jones and Bill Murray. This trailer really got me excited, and I’m thinking it might be the perfect cinematic companion to a thorough ring test.

So, grab your supplies and get ready to test!

Their versatility stems from the flexibility of the test design and the ability to adapt to various materials and conditions. This adaptable nature makes ring tests a valuable tool for quality control and process optimization.

Real-World Application in Manufacturing, Do a Ring Test

Ring tests play a crucial role in maintaining consistent product quality in manufacturing. They can detect minute variations in material properties or process parameters that might otherwise go unnoticed. This early detection of deviations prevents significant issues later in the production chain, leading to cost savings and improved product reliability.

- Quality Control in Metal Fabrication: In a steel manufacturing facility, a ring test was used to monitor the consistency of the quenching process. Variations in quenching temperature resulted in inconsistencies in the hardness of the final product. By implementing a ring test protocol, the facility identified the specific point in the quenching process where the temperature was fluctuating. This allowed them to adjust the temperature control system, ensuring a uniform hardness across all batches, significantly improving product quality and reducing waste.

- Pharmaceutical Manufacturing: A pharmaceutical company used ring tests to evaluate the uniformity of tablet compression. The ring test revealed inconsistencies in the tablet compression force, resulting in varying dissolution rates. By adjusting the compression machine settings, the company ensured a consistent tablet structure and improved the drug’s efficacy. This highlights how ring tests can help maintain precise dosage consistency in pharmaceuticals.

Impact on Environmental Monitoring

Ring tests can be adapted for environmental monitoring, helping researchers detect subtle changes in water or soil quality. The ease of implementation and the relative speed of results make ring tests an effective tool for tracking environmental degradation and assessing the impact of pollution.

- Assessing Water Contamination: A research team used a ring test to monitor the concentration of heavy metals in a river. By observing the color change in the ring test solution, they were able to detect subtle increases in metal concentrations, signaling potential pollution sources and allowing for timely interventions.

A Detailed Case Study: Polymer Degradation

To illustrate the practical application, consider a case study involving polymer degradation.

Problem: A plastic manufacturing company noticed inconsistencies in the durability of their plastic pipes. The pipes were failing prematurely, leading to significant production losses and customer complaints. The problem was localized, appearing in specific batches of pipes.

Methodology: A ring test was designed to assess the tensile strength of the polymer samples. The ring test samples were taken from different production batches. The test was conducted using a standardized ring test methodology, which involved subjecting the rings to a controlled tensile force. The result was recorded by the amount of force needed to break the ring.

This data provided a clear indication of the strength of the material.

Results: The ring test revealed that a specific batch of polymer feedstock had a significantly lower tensile strength compared to the other batches. This batch showed a noticeable decrease in the force required to break the rings. This indicated that the polymer was degrading during the manufacturing process. The specific point of degradation could be identified by looking at the results of different batches.

Conclusions: The ring test identified the cause of the problem, enabling the company to isolate and correct the issue in the production process. They were able to pinpoint a specific stage in the manufacturing process where the polymer degradation was occurring. This proactive approach to quality control saved the company substantial financial losses and improved customer satisfaction.

Equipment and Materials: Do A Ring Test

The success of any ring test hinges on the meticulous selection and proper use of equipment and materials. Carefully chosen tools ensure accurate measurements and reliable results, while high-quality materials prevent inconsistencies that could skew the data. Understanding the specific needs of each ring test type is crucial for obtaining meaningful and comparable outcomes.

Essential Equipment for Ring Tests

The necessary equipment for ring tests varies depending on the specific type of test being conducted. Some common tools include precision measuring instruments, specialized clamping devices, and appropriate environmental controls. Accurate measurements are paramount for obtaining reliable results.

- Calibration Equipment: Accurate calibration is critical for ensuring reliable measurements. This includes calibrated micrometers, calipers, and verniers for precise dimensional measurements. These tools are vital for establishing the baseline for comparison and ensuring consistency throughout the test process.

- Clamping Devices: The selection of clamping devices is critical to secure the ring samples and prevent movement during testing. Various clamping systems are designed to hold the samples in the desired orientation, minimizing stress concentrations and ensuring consistent results. Specialized clamping devices are often required to handle the particular shape and size of the rings being tested.

- Environmental Control Systems: Controlling environmental factors such as temperature and humidity is crucial for maintaining consistent testing conditions. This includes temperature-controlled chambers and humidity regulators. These systems help to ensure that the testing environment remains consistent and minimizes the impact of external variables on the results.

Materials for Ring Tests

The materials used in ring tests are equally important. The quality of these materials directly affects the accuracy and reproducibility of the results. Consistency and homogeneity of the material are paramount for obtaining meaningful data.

- Ring Samples: The ring samples themselves are critical to the outcome of the test. The material’s composition, purity, and dimensions must be well-documented. Uniformity in the material composition is crucial to avoid variations in the test results.

- Reference Standards: Accurate reference standards are necessary for comparison. These standards should be traceable to recognized national or international standards. They provide a benchmark against which the ring samples can be evaluated.

- Lubricants (if applicable): In some ring tests, lubricants are required to reduce friction and ensure smooth operation. The selection of lubricants should consider their compatibility with the ring material and the test conditions.

Importance of Quality

The quality of both the equipment and the materials used in ring tests directly impacts the reliability of the results. Variations in equipment calibration or material inconsistencies can introduce errors and affect the overall validity of the conclusions drawn. Consistent quality ensures that the results are repeatable and comparable across different tests and laboratories.

Equipment Suitability Table

| Equipment Type | Specifications | Suitability for Ring Tests |

|---|---|---|

| Micrometer | Precision: 0.001 mm | Ideal for precise dimensional measurements, especially for internal and external diameters. |

| Calipers | Precision: 0.01 mm | Suitable for general dimensional measurements and checking for consistency across different samples. |

| Tensile Testing Machine | Load capacity: 50 kN | Appropriate for determining the tensile properties of ring samples, including stress-strain behavior. |

| Hardness Tester | Indentation depth measurement: 0.001 mm | Useful for assessing the hardness of ring samples and correlating with other material properties. |

| Temperature-controlled chamber | Temperature range: 20-40°C, accuracy: ±0.1°C | Essential for ensuring consistent temperature during ring tests, particularly for materials sensitive to temperature variations. |

Closing Summary

In conclusion, Do a Ring Test offers a powerful tool for quality assessment and process optimization. By understanding the diverse types of ring tests, the methodology, and the crucial aspects of data analysis, professionals can leverage this technique effectively. This guide serves as a valuable resource for anyone looking to implement or improve ring test procedures within their operations.

The key takeaway is that a thorough understanding of the principles, methodology, and applications of ring tests is essential for accurate results and effective problem-solving.

Leave a Reply